Ultimate Guide to Perforating Gun Shot Analysis

By:Admin

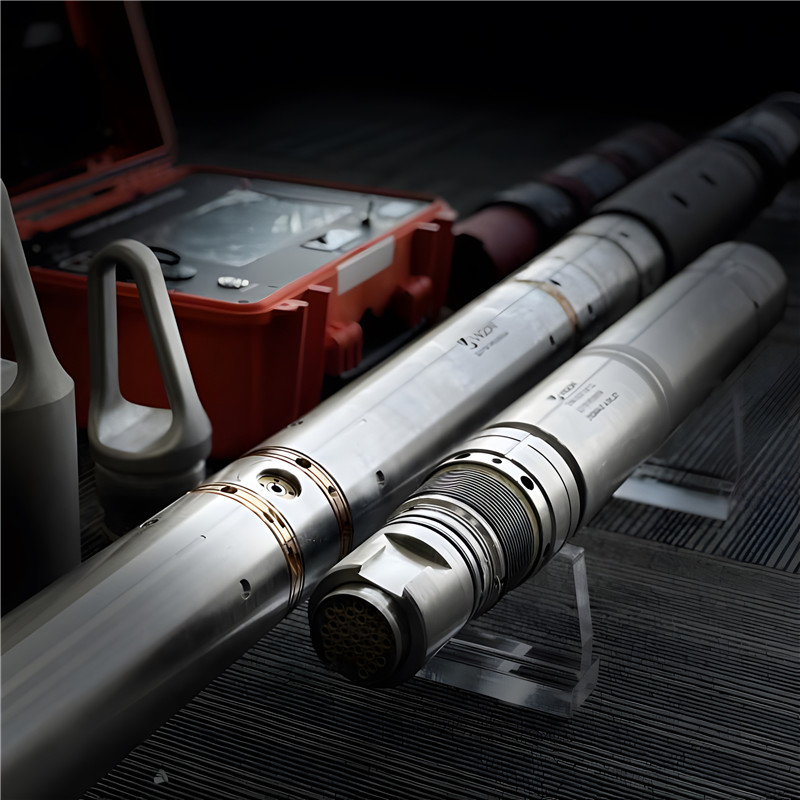

The perforating gun shot analysis has revealed significant advancements in the oil and gas industry, thanks to innovative technology developed by a leading oilfield services company, {}. This groundbreaking technology has the potential to revolutionize the way oil and gas wells are perforated and ultimately enhance production efficiency.

{} is a global leader in providing innovative solutions for the oil and gas industry. With a strong focus on research and development, the company has continually pushed the boundaries of technology to improve well performance and maximize production. Their latest innovation in perforating gun shot analysis is a testament to their commitment to driving technological advancement in the industry.

The perforating gun shot analysis is a critical process in the oil and gas industry, as it involves the use of explosives to create openings in wellbore casing and cement, allowing for the flow of hydrocarbons from the reservoir to the surface. Traditionally, this process has been somewhat challenging to analyze and optimize, requiring extensive testing and evaluation to achieve the desired results.

However, {} has developed a proprietary technology that allows for real-time analysis of perforating gun shots, providing valuable data and insights that can be used to optimize well performance. This technology has the potential to significantly improve the efficiency and effectiveness of perforating operations, leading to increased production and reduced costs for operators.

The key to this innovative technology lies in its ability to accurately measure the performance of each perforating gun shot, including factors such as penetration depth, hole size, and distribution. By capturing and analyzing this data in real time, operators are able to make informed decisions regarding well completion and production strategies, ultimately leading to improved overall performance.

In addition to the real-time analysis capabilities, this technology also offers advanced modeling and simulation tools that enable operators to predict and optimize perforating gun shot performance before the actual operation takes place. This predictive capability can help to mitigate risks and improve overall operational efficiency, ultimately leading to cost savings and improved well productivity.

The impact of this technology is far-reaching, as it has the potential to benefit operators across the oil and gas industry. From onshore to offshore operations, this innovative solution can help to optimize well performance and maximize production, ultimately leading to enhanced profitability and sustainability.

As the oil and gas industry continues to evolve, technological innovation will be a driving force in improving operational efficiency and reducing costs. With the development of advanced solutions such as the perforating gun shot analysis technology by {}, the industry is poised to achieve new levels of performance and productivity.

The potential impact of this technology on the oil and gas industry cannot be understated, as it has the potential to revolutionize the way operators approach well completion and production. By providing real-time analysis and predictive capabilities, this innovative solution has the power to unlock new levels of efficiency and productivity, ultimately leading to improved profitability for operators.

In conclusion, the perforating gun shot analysis technology developed by {} represents a significant advancement in the oil and gas industry. With its real-time analysis and predictive capabilities, this innovative solution has the potential to revolutionize well completion and production, ultimately leading to improved operational efficiency and profitability for operators. As the industry continues to embrace technological innovation, solutions such as this will play a pivotal role in driving the future of oil and gas production.

Company News & Blog

Innovative Drilling Equipment Designed to Improve Bypass Efficiency

Drilling Bypass Equipment Revolutionizes Oil and Gas IndustryHouston, Texas - A revolutionary technology in the oil and gas industry is capturing the attention of industry experts and professionals. The new drilling bypass equipment has been developed by a leading company, which is committed to providing cutting-edge solutions to the oil and gas sector. The highly advanced drilling bypass equipment (name removed) sets a new benchmark for performance and safety in drilling operations.The traditional method of drilling involves the use of a cement plug, which separates the drilling fluids from the reservoir during deep drilling operations. However, when cementing goes wrong, the result is often stuck pipe, lost circulation, and other drilling complications. On the other hand, Drilling bypass equipment has proven to be an effective solution that enhances drilling safety and efficiency.The high-grade drilling bypass equipment comprises multifarious parts, including adjustable valve gear, crossover tools, and a sealing assembly, among others. With its extensive and robust design, the equipment creates a safe and reliable bypass around the cement plug. As a result, it increases the drilling safety margin, saves time, and reduces drilling costs significantly.Furthermore, the drilling bypass equipment provides considerable flexibility to the drilling operation. The equipment enables drilling to bypass the unwanted formation, damaged pipe or wellbore obstruction. The bypass is then created, and the drilling team can proceed with the planned operation without any disruption. The equipment also minimizes HSE risks, reduces the possibility of formation damage, and eliminates non-productive time (NPT).In a statement to the press, the company's CEO said, "We are thrilled to introduce drilling bypass equipment as it represents a significant milestone in the oil and gas sector. Our team has worked tirelessly to develop and optimize this technology, and we are extremely proud of the results. With the drilling bypass equipment, we aim to augment the drilling industry's efficiency, productivity, and safety. We envision the equipment becoming a staple in the industry and a key contributor to our clients' operational success."The drilling bypass equipment has undergone exhaustive testing and validation at various stages to ensure maximum efficiency and compliance with industry safety standards. The equipment's durability and effectiveness have been tested in challenging drilling environments, including high-pressure high-temperature (HPHT), deepwater, and harsh environments. Consequently, clients can be confident that the equipment will perform optimally in any drilling condition.Notably, one of the significant advantages of the drilling bypass equipment is enhanced drilling fluid recirculation, which reduces drilling costs. The equipment optimizes the recirculation of drilling fluids, ensuring they are used efficiently, thereby reducing the volume of unused fluids that need to be disposed of after the drill is completed. This directly translates to cost savings for drilling operations and reduces the environmental impact of drilling.The drilling bypass equipment comprises a broad range of bypass technologies, suitable for both new and existing wells. Its capability to create bypasses around critical wellbore obstructions makes it a vital tool for repairing damaged wells and restoring the production flow. The bypasses can also be used to inject steam, gas, or other fluids into the formation to improve production rates.In conclusion, the drilling bypass equipment is a game-changer for the oil and gas industry, providing drillers with high performance and safe drilling operations. The system's cost-saving, production enhancing, and safety-enhancing features all stand to revolutionize the industry. The drilling bypass equipment is now available for purchase and installation, and interested parties are encouraged to contact the company for more information.

Exploring the Efficiency of Jet Perforating Carriers in Resource Extraction

Jet Perforating Carrier, a cutting-edge technology in the oil and gas industry, is revolutionizing the way wells are drilled and completed. This advanced system, developed by a leading oilfield services company, is set to enhance efficiency, improve safety, and maximize production. With its innovative features and exceptional design, the Jet Perforating Carrier promises to be a game-changer in the field.The Jet Perforating Carrier is a state-of-the-art tool that is used in perforating operations during well completion. Perforation is a critical process in the oil and gas industry, where small explosive charges are used to create holes in the well casing, allowing oil and gas to flow into the wellbore. Traditionally, this process involved the use of wireline guns, which have several limitations, including limited control over the depth and orientation of the perforations.However, the Jet Perforating Carrier tackles these challenges head-on. Its unique design allows for precise, controlled, and directional perforations, enabling operators to target specific zones of the reservoir with accuracy. This leads to enhanced well productivity and reduced cost. Additionally, the carrier can be used in a variety of well types, including vertical, horizontal, and deviated wells, making it a versatile solution for diverse drilling conditions.One of the major advantages of the Jet Perforating Carrier is its ability to eliminate the need for wireline operations. This not only saves time and cost but also enhances safety. By removing the need for wireline guns, which involve personnel on the wellsite, the risk of accidents and injuries is significantly reduced. The carrier operates autonomously, providing a safer and more reliable perforation process.Another key feature of the Jet Perforating Carrier is its efficient and reliable perforation performance. The carrier is equipped with advanced technologies that enable high-precision pressure control during the perforation process. This ensures optimal hole diameter and depth, leading to improved well productivity. Moreover, the carrier can be equipped with real-time monitoring systems, allowing operators to track and analyze the perforation process in real-time, further enhancing efficiency and productivity.Furthermore, the Jet Perforating Carrier is designed with sustainability in mind. It minimizes environmental impact by reducing the number of perforation shots required to achieve the desired results. This not only decreases the amount of explosives used but also reduces waste production. The carrier's efficient and controlled perforation process translates into a more sustainable drilling operation, aligning with the industry's growing focus on environmental responsibility.With these exceptional features and benefits, it is no surprise that the Jet Perforating Carrier has been met with great anticipation and interest in the oil and gas industry. Operators and drilling companies are eager to incorporate this innovative technology into their operations to optimize well productivity and increase profitability.In conclusion, the Jet Perforating Carrier is set to revolutionize well completion processes in the oil and gas industry. Its advanced features, including precise and directional perforations, elimination of wireline operations, reliable performance, and environmental sustainability, make it a highly sought-after technology. With the potential to enhance efficiency, improve safety, and maximize production, the Jet Perforating Carrier is poised to be a game-changer in the field, marking a significant advancement in well completion operations.

Advanced Gyroscope Technology Revolutionizes Drilling Navigation

Title: Revolutionary Drilling Navigation Gyroscope Aims to Revolutionize the Oil and Gas IndustryIntroduction:As the global demand for energy continues to grow, the oil and gas industry is constantly striving to innovate and optimize its drilling operations. In a breakthrough development, a cutting-edge Drilling Navigation Gyroscope has been unveiled by an industry-leading company. Leveraging advanced technology and precision engineering, this state-of-the-art gyroscope promises to dramatically enhance drilling navigation, resulting in improved efficiency, accuracy, and safety in the oil and gas sector.Body:1. Overview of the Drilling Navigation Gyroscope:The newly introduced Drilling Navigation Gyroscope, developed by an innovation-driven company, is set to redefine the standards of drilling technology. By utilizing advanced gyroscopic principles, this groundbreaking device provides drilling operators with real-time, accurate, and reliable data crucial for efficient drilling operations.2. Enhanced Accuracy and Efficiency:With the incorporation of cutting-edge technology, the Drilling Navigation Gyroscope offers unparalleled levels of precision, allowing drilling operations to be carried out with utmost accuracy. By eliminating discrepancies in measurements, operators can minimize costly errors and optimize drilling procedures, resulting in increased productivity and operational efficiency.3. Real-Time Navigation Feedback:Traditionally, drilling operations can encounter difficulties due to misalignments or inaccurate positioning. However, with the integration of the Drilling Navigation Gyroscope, operators now have access to real-time navigation feedback, ensuring precise alignment and positioning of drilling equipment. This unprecedented feature significantly reduces the time and effort required for corrective actions, enabling project timelines to be adhered to more effectively.4. Safety Advancements:The Drilling Navigation Gyroscope prioritizes safety measures by providing operators with a comprehensive view of the drilling site. By accurately mapping underground formations, the gyroscope assists in identifying potential hazards, such as unstable areas or gas pockets, allowing proactive safety measures to be implemented. This proactive approach enhances operational safety, mitigating risks and protecting human lives.5. Cost Optimization:The incorporation of the Drilling Navigation Gyroscope is expected to have a substantial impact on cost optimization within the oil and gas industry. By minimizing the likelihood of costly drilling mistakes, including inefficient drilling paths and unplanned sidetracks, operators can save both time and resources. The resulting efficiency gains contribute to overall cost reduction and enhance the industry's profitability.6. Remote Monitoring and Data Analysis:The Drilling Navigation Gyroscope enables remote monitoring of drilling operations, safeguarding personnel by reducing the need for on-site presence. Vital drilling data acquired by the gyroscope, such as wellbore trajectory, wellbore speed, and drilling dynamics, can be monitored and analyzed remotely. This innovative feature enhances decision-making processes, facilitates streamlined operations, and boosts productivity.7. Environmental Impact:In addition to revolutionizing drilling operations, the Drilling Navigation Gyroscope also delivers environmental benefits. With improved accuracy and navigation capabilities, operators can avoid unnecessary drilling, reducing the environmental footprint associated with exploration activities. Such an advancement aligns with the industry's commitment towards sustainable practices and contributes to minimizing environmental impact.Conclusion:The introduction of the Drilling Navigation Gyroscope represents a significant leap forward for the oil and gas industry. Through its advanced technology, precision engineering, and real-time navigation feedback, this innovative device is set to optimize drilling operations, ensuring accuracy, efficiency, and safety. Furthermore, its integration will result in cost reductions, remote monitoring capabilities, and environmental benefits. As the demand for energy remains unabated, such advancements will play a pivotal role in meeting global energy needs sustainably.

Essential Drilling Circulation Equipment for Improved Efficiency

Drilling Circulation Equipment Leads the Way in Efficiency and SafetyDrilling for oil and gas is a complex and intricate process that requires precision, efficiency, and above all, safety. In order to achieve these goals, companies rely on advanced drilling circulation equipment to ensure the smooth and successful operation of their drilling projects. One such company that has been making waves in this industry is {}, which has been at the forefront of developing cutting-edge drilling circulation equipment that meets the highest standards of performance and safety.Founded in the early 2000s, {} has quickly established itself as a leader in the manufacturing and distribution of drilling equipment for the oil and gas industry. The company's commitment to innovation, reliability, and customer satisfaction has earned it a reputation as a trusted and esteemed provider of drilling circulation equipment.One of the key products that has set {} apart from its competitors is its range of drilling mud pumps. These pumps play a crucial role in the drilling process by circulating drilling mud – a mixture of water, clay, and other additives – through the drill string and back to the surface. This process helps to cool the drill bit, carry rock cuttings to the surface, and provide pressure to prevent blowouts and well control issues.{}'s drilling mud pumps are designed and manufactured with the highest quality materials and engineering precision, ensuring that they can withstand the demanding conditions of drilling operations. With a focus on durability, efficiency, and safety, {}'s mud pumps have become an essential component of drilling projects around the world.In addition to its mud pumps, {} also offers a comprehensive range of related drilling circulation equipment, including solid control systems, shale shakers, degassers, and centrifuges. These products are designed to work seamlessly together to ensure the smooth and efficient circulation of drilling fluids, contributing to the overall success of drilling operations.In recent years, {} has further solidified its position as a leader in the industry by investing in research and development to continuously improve its products. The company's team of engineers and technicians work tirelessly to innovate and enhance the performance of its drilling circulation equipment, taking into account the evolving needs and challenges of the oil and gas industry.Furthermore, {} is committed to upholding the highest standards of safety in the design and manufacturing of its products. The company's equipment undergoes rigorous testing and quality assurance processes to ensure that it meets or exceeds industry standards for reliability and safety. With a focus on preventing accidents and minimizing environmental impact, {}'s drilling circulation equipment is trusted by drillers and operators worldwide.As the global demand for oil and gas continues to grow, the need for efficient and reliable drilling circulation equipment has never been greater. {}'s commitment to excellence and innovation has positioned the company as a leading provider of these essential tools for the oil and gas industry.In conclusion, {} has set itself apart as a trusted and respected provider of drilling circulation equipment, offering a range of high-quality products that are essential for the success and safety of drilling operations. With a focus on innovation, reliability, and safety, {} is well positioned to continue leading the way in this vital industry.

Discover the Benefits of 3 1/8" Bridge Plugs for Your Projects

[Company Name] Introduces State-of-the-Art Bridge Plugs for Efficient Oil and Gas Well Operations[date][City, State] - [Company Name], a leading provider of innovative oil and gas well solutions, is thrilled to announce the launch of its latest product line, the next-generation 3 1/8" Bridge Plugs. Designed to optimize well operations and improve efficiency, these bridge plugs are set to revolutionize the oil and gas industry.With a commitment to delivering high-quality products that meet the ever-changing demands of the market, [Company Name] has invested heavily in research and development to create an advanced bridge plug that guarantees superior performance. The 3 1/8" Bridge Plugs offer enhanced reliability and durability, ensuring efficient well isolation and maximum productivity during oil and gas extraction processes.One of the key features of the new bridge plugs is their innovative design, which enables easy and secure installation. The plug's compact size and streamlined shape make it suitable for a wide range of wellbore applications, including both vertical and horizontal wells. Its compatibility with various drilling fluids, including oil-based and water-based fluids, ensures versatility in any drilling operation.The 3 1/8" Bridge Plugs are manufactured using cutting-edge materials and technologies, ensuring optimum performance in extreme temperatures and high-pressure environments. This robust construction guarantees that the plugs can withstand the most demanding well conditions without compromising integrity or functionality.Additionally, [Company Name]'s bridge plugs are equipped with industry-leading sealing mechanisms, guaranteeing a reliable seal and preventing any unwanted fluid migration. The secure isolation provided by these plugs not only ensures safety during operations but also minimizes any potential environmental risks."We are extremely excited about the launch of our 3 1/8" Bridge Plugs," said [Company Name]'s CEO. "At [Company Name], we continually strive to develop innovative tools that exceed industry standards. These bridge plugs are a testament to our commitment to providing our customers with state-of-the-art solutions that enhance operational efficiency and reduce costs."Furthermore, these bridge plugs are part of [Company Name]'s dedication to sustainability. By enhancing operational efficiency, the 3 1/8" Bridge Plugs contribute to reducing the environmental impact associated with well drilling. Additionally, their robustness and durability reduce the need for frequent replacements, promoting a more sustainable and cost-effective approach to well operations.In line with [Company Name]'s customer-centric approach, the 3 1/8" Bridge Plugs come with comprehensive technical support from highly skilled engineers and technicians. This includes on-site assistance, expert advice, and customized training programs to ensure optimal plug installation and operation.With their unique features, the 3 1/8" Bridge Plugs provide oil and gas operators with a competitive edge in terms of efficiency, safety, and cost-effectiveness. By choosing [Company Name]'s bridge plugs, clients can expect reduced downtime, minimized risks, and improved overall well performance.About [Company Name]:[Company Name] is a dedicated provider of cutting-edge solutions for the oil and gas industry. With a focus on innovation and customer satisfaction, [Company Name] continues to develop and deliver industry-leading products and services. From well intervention tools to well completion technologies, [Company Name] offers a comprehensive range of solutions that optimize well productivity and maximize returns for its clients.For more information about [Company Name] and its latest 3 1/8" Bridge Plugs, please visit [company website] or contact [company representative] at [contact details].###

Benefits of Perforation in Oil and Gas Industry

Title: Leading Oilfield Service Provider Introduces Jet Perforation Technology for Enhanced Well ProductivityIntroduction:[Company Name], a pioneer and global leader in oilfield services, is revolutionizing the oil and gas industry with its cutting-edge jet perforation technology. With a strong commitment to innovation and technological advancements, [Company Name] continues to deliver superior solutions that drive increased well productivity. This game-changing technology is set to transform the industry and boost production yields for its clients worldwide.Body:I. The Advancement in Jet Perforation TechnologyJet perforation, also known as high-pressure perforation, is a technique used in the oil and gas industry to create perforations or channels in the well casing to improve fluid flow from the reservoir to the wellbore. Traditional perforation techniques often face limitations in achieving optimal flow rates due to formation damage and reduced productivity.[Company Name]'s state-of-the-art jet perforation technology addresses these challenges by delivering precise and controlled high-pressure jet streams. This innovative method effectively creates perforations without causing excessive damage to the formation, resulting in enhanced reservoir connectivity and improved overall well productivity.II. Key Features and Benefits of Jet Perforation Technologya) Unique Nozzle Design: [Company Name]'s jet perforation technology incorporates a meticulously engineered nozzle design that efficiently distributes the high-pressure jet streams evenly across the entire perforation interval. This ensures consistent and uniform perforations, reducing flow restrictions and maximizing hydrocarbon recovery.b) Optimal Penetration and Efficiency: The advanced technology propels the high-pressure jets precisely through the well casing, penetrating the formation rock with precision and efficiency. This targeted approach minimizes damage to the surrounding rock and enables enhanced reservoir connectivity, leading to increased production rates.c) Enhanced Fluid Flow: Jet perforation technology creates larger, cleaner perforation tunnels compared to conventional techniques, enabling improved fluid flow rates. This results in reduced drawdown pressure and enhanced well performance, ultimately driving higher oil and gas yields for operators.d) Reduced Risk of Damage: By carefully controlling pressure and utilizing advanced perforation modeling techniques, [Company Name] minimizes the risk of damaging the wellbore and formation. As a result, the integrity of the well is maintained, preventing costly operational issues and extending the productive life of the asset.III. Implementation of Jet Perforation Technology in Real-World Scenarios[Company Name]'s jet perforation technology has proven its dominion in a range of challenging environments, demonstrating its versatility and effectiveness across various drilling conditions. The company's advanced engineering expertise and experience ensure that it can tailor the technology to optimize reservoir connectivity and productivity, irrespective of the formation characteristics.Whether in complex shale formations or high-temperature/high-pressure offshore wells, [Company Name]'s jet perforation technology has showcased exceptional performance. By deploying advanced computational fluid dynamics and extensive laboratory testing, the company ensures the technology's reliability and robustness in diverse applications.IV. Future Implications and Market ImpactAs the global demand for energy continues to rise, the need for efficient and sustainable extraction methods becomes increasingly crucial. [Company Name]'s jet perforation technology is positioned to play a significant role in maximizing hydrocarbon recovery while minimizing environmental impact.By increasing well productivity, reducing production costs, and extending the life cycles of oil and gas fields, companies using jet perforation technology can enjoy substantial economic benefits. Moreover, this technology aligns with the industry's push for improved environmental stewardship by reducing the number of wells required to achieve production targets.[Company Name]'s commitment to continuous research and development ensures that jet perforation technology will continue to evolve, offering even more efficient and effective solutions for its clients. By staying at the forefront of oilfield services, [Company Name] reinforces its position as a leading provider of innovative technologies that drive the industry forward.Conclusion:[Company Name]'s groundbreaking jet perforation technology is poised to revolutionize the oil and gas industry, offering enhanced well productivity and improved fluid flow rates. With its unique features and numerous benefits, this innovative solution promises to optimize reservoir connectivity and increase production yields.As a global pioneer in oilfield services, [Company Name] continues to push the boundaries of technology, providing its clients with advanced solutions to address the industry's challenges. By harnessing the power of jet perforation, operators can foster more efficient and sustainable energy production while maximizing their return on investment.

Cutting-Edge Wireline Setting Tool Boosts Efficiency and Precision

Innovation is at the forefront of the oil and gas industry, and the introduction of the BK10 Wireline Setting Tool is a prime example of this. The product, developed by a leading oil and gas technology company, promises to revolutionize wireline service, a key component of the industry.Wireline service involves the use of cables to lower tools and instruments into a wellbore to assess its condition, collect data and ultimately, enhance production. It is an essential service that is used in drilling, completion and production processes. Despite its importance, wireline service has faced challenges in reliability, efficiency and safety. The BK10 Wireline Setting Tool was designed to address these challenges and provide a reliable, efficient and safe solution for wireline service.The BK10 Wireline Setting Tool is a state-of-the-art tool that can be used to set and retrieve wireline tools quickly and safely. It is designed to be easy to use, with a simple interface that can be operated by experienced and novice users alike. The tool is engineered with a range of features that make it extremely reliable. It is constructed from high-quality materials, making it resistant to wear and tear and durable enough to withstand harsh conditions.The most significant feature of the BK10 Wireline Setting Tool is its ability to reduce the time it takes to set and retrieve wireline tools. Traditionally, wireline service can be time-consuming, with the need to stop operations while tools are lowered into the wellbore, retrieved and then reset. The BK10 Wireline Setting Tool, however, can significantly reduce this time by automating the process. It is a game-changer, enabling companies to complete their work faster and, ultimately, more efficiently.Safety is also a significant concern in the oil and gas industry, and the BK10 Wireline Setting Tool takes safety very seriously. It is designed with multiple layers of protection that ensure safe operation. For example, it is equipped with a smart latch release system that prevents the tool from being accidentally released, reducing the risk of injury and equipment damage. The tool also includes a wireless monitoring system that enables real-time monitoring of the tool's performance and alerts operators to any potential issues.In addition to its excellent performance and safety features, the BK10 Wireline Setting Tool is also cost-effective. By reducing the time it takes to set and retrieve wireline tools, companies can reduce their operational costs and increase their productivity. It is an investment that promises to pay off for oil and gas companies of all sizes.The BK10 Wireline Setting Tool is a product that underscores the importance of innovation in the oil and gas industry. With its game-changing features, it is an excellent example of how new technologies are driving the industry forward, and companies that invest in innovation will be the ones to succeed in the years to come.The company that developed the BK10 Wireline Setting Tool has a reputation for innovation, and the success of this product is a testament to its commitment to innovation and research and development. The company has a long history of developing cutting-edge technologies that help companies succeed in the oil and gas industry. The BK10 Wireline Setting Tool is just one example of the company's excellent product range, which includes a range of tools and services designed to improve safety, efficiency and productivity.In conclusion, the BK10 Wireline Setting Tool is an innovative product that promises to revolutionize wireline service. It is a game-changer, offering significant improvements in speed, safety and productivity. With its commitment to innovation, the company that developed the tool has demonstrated its ability to meet the needs of the oil and gas industry and position itself as a leader in the market. The BK10 Wireline Setting Tool is a product that will help companies operate more efficiently and safely, and ultimately, succeed in the highly competitive oil and gas industry.

Revolutionary Bridge Plug Drilling Unveiled - A Game-Changer in the Energy Industry

Title: Innovative Bridge Plug Drilling Technology Revolutionizing the Oil and Gas IndustryIntroduction:XX Drilling, a leading provider of cutting-edge drilling solutions, has introduced a groundbreaking bridge plug drilling technology that is set to transform the oil and gas industry. With a commitment to innovation and efficiency, XX Drilling aims to revolutionize wellbore integrity and improve productivity for operators worldwide. This advanced technology eliminates the need for traditional bridge plug deployment methods, offering substantial cost savings, increased operational flexibility, and enhanced safety measures.Bridge Plug Drilling - A Game-Changer in the Oil and Gas Industry:XX Drilling's bridge plug drilling technology combines state-of-the-art equipment and advanced engineering techniques to enable seamless wellbore isolation. Traditionally, setting bridge plugs required multiple operations involving deployment and retrieval, resulting in significant time and cost expenditures. However, XX Drilling has redefined this process by developing a pioneering method that eliminates the need for secondary drilling and reduces overall operational complexity.With XX Drilling's bridge plug drilling technology, operators can deploy plugs directly during drilling operations, allowing for the isolation of distinct sections of the wellbore for reservoir evaluation, pressure testing, or the prevention of unwanted fluid migration. This eliminates the need to remove the entire drill string and re-run the casing, saving operators significant time and resources.Superior Performance and Safety Measures:The XX Drilling bridge plug drilling system incorporates cutting-edge components that ensure superior performance and safety. The technology comprises advanced plug designs, including fast-acting, retrievable, and biodegradable plugs, enhancing adaptability and optimizing plug performance based on specific well conditions. These innovative plug options reduce potential environmental risks and minimize costly interventions.Furthermore, XX Drilling's bridge plug drilling technology offers real-time communication and monitoring capabilities, allowing operators to make data-driven decisions and adapt their drilling strategies accordingly. With enhanced visibility into downhole conditions, operators can prevent potential issues and improve overall drilling efficiency.Operational Flexibility and Cost-Effectiveness:By seamlessly integrating bridge plug deployment into the drilling process, XX Drilling enables increased operational flexibility and cost-effectiveness. Traditional methods often require multiple trips in and out of the wellbore, resulting in increased non-productive time and associated costs. However, with the implementation of XX Drilling's technology, operators can bypass these repetitive steps, leading to substantial cost savings.Additionally, the ability to selectively isolate specific sections of the wellbore reduces the need for additional equipment, such as packers and intermediate casing strings, contributing to further cost savings. This streamlined approach offers operators increased flexibility, allowing for various interventions and reducing project timelines.Environmental Considerations:XX Drilling's commitment to sustainable drilling practices is also evident in the environmental considerations built into their bridge plug drilling technology. The use of biodegradable plugs minimizes the environmental footprint, ensuring a greener and more responsible approach to wellbore integrity.Conclusion:With the introduction of their bridge plug drilling technology, XX Drilling aims to revolutionize the oil and gas industry by offering operators a more efficient, cost-effective, and environmentally conscious method of wellbore isolation. Through their commitment to innovation, the company is poised to transform drilling practices, bringing substantial benefits to operators worldwide. As the industry continues to evolve, XX Drilling's cutting-edge technology is set to lead the way towards a safer, more productive, and environmentally sustainable future.

Revolutionary Technology for Optimizing Drilling Bypass

[Company Name] Revolutionizes Drilling Bypass Optimization for Enhanced Efficiency in Oil and Gas Industry[Hometown], [Date] - [Company Name], a renowned player in the oil and gas industry, has recently unveiled its groundbreaking Drilling Bypass Optimization technology. This innovative solution is poised to revolutionize drilling operations by significantly increasing efficiency and reducing costs. By harnessing advanced data analytics and intelligent algorithms, [Company Name] aims to drive a paradigm shift in drilling practices, making them more streamlined and sustainable.Drilling bypass optimization involves the process of analyzing and interpreting data collected during drilling operations to identify areas of improvement and enable real-time decision-making. Traditional drilling processes often rely on outdated methods, causing inefficiencies, drilling hazards, and unnecessary expenses. In contrast, [Company Name]'s cutting-edge technology leverages a combination of artificial intelligence, predictive modeling, and machine learning to optimize drilling performance while ensuring environmental sustainability.The key to [Company Name]'s Drilling Bypass Optimization technology lies in its ability to gather and process massive amounts of drilling data in real-time. This includes information on drilling speed, pressure levels, temperature changes, rock formations, and equipment condition, among others. By deploying advanced sensors and data acquisition algorithms, the technology captures and interprets this data to create a comprehensive, real-time picture of drilling operations.Through their proprietary machine learning algorithms, [Company Name] analyzes the data to identify patterns, anomalies, and potential issues that may arise during drilling. This allows operators to proactively address any risks or inefficiencies and make immediate adjustments to optimize drilling operations. The ability to make timely decisions based on accurate data ensures minimal downtime and maximizes drilling efficiency.In addition to enhancing drilling efficiency, [Company Name]'s Drilling Bypass Optimization technology also prioritizes environmental sustainability. By minimizing drilling issues and promoting efficient drilling practices, the technology helps reduce the overall carbon footprint associated with drilling operations. This aligns with the industry's increasing focus on sustainability and minimizing environmental impact, making [Company Name] a key player in driving the adoption of eco-friendly practices.Beyond the direct benefits to drilling operations and the environment, [Company Name] believes that the deployment of its Drilling Bypass Optimization technology will also lead to significant cost savings for oil and gas companies. By mitigating drilling hazards, reducing non-productive time, and maximizing resource utilization, companies can achieve substantial financial savings in their operations. This comes at a crucial time for the industry, which has been facing economic uncertainties amidst fluctuating oil prices and increasing competition.Testimonials from early adopters of [Company Name]'s Drilling Bypass Optimization technology have been overwhelmingly positive. Various drilling companies have reported increased operational efficiency by up to 30% and significant reductions in drilling-related costs. The combination of real-time data analytics and intelligent decision-making has proven to be a game-changer in improving drilling performance.Looking ahead, [Company Name] plans to further enhance its Drilling Bypass Optimization technology by integrating additional features, such as remote monitoring and control capabilities. This will enable drilling operators to make informed decisions and adjustments without physical intervention, improving both safety and efficiency. The team at [Company Name] recognizes the need for continuous innovation in the oil and gas industry and remains committed to developing cutting-edge solutions to address industry challenges.With the introduction of its Drilling Bypass Optimization technology, [Company Name] is cementing its position as a frontrunner in optimizing drilling operations. By combining data analytics, machine learning, and a commitment to sustainability, [Company Name] offers a holistic solution that drives efficiency, reduces costs, and minimizes environmental impact. As the industry seeks innovative approaches to overcome challenges and improve performance, [Company Name] is poised to shape the future of drilling operations.

Boosting Perforation Productivity: Key Factors for Improved Results

Perforation Productivity Revolutionizes the Oil and Gas IndustryThe oil and gas industry has always been one of the most significant sectors in the global economy. The extraction of hydrocarbon resources requires sophisticated equipment and advanced techniques to maximize productivity and profitability. In this regard, Perforation Productivity has emerged as a leading provider of cutting-edge solutions, revolutionizing the industry by significantly enhancing well production and efficiency.Founded in [year of establishment], Perforation Productivity has been at the forefront of technological advancements in the oil and gas industry. The company specializes in developing and manufacturing innovative perforation systems that enable efficient penetration of wellbores, enhancing fluid flow and reservoir connectivity.One of the key strengths of Perforation Productivity lies in its commitment to research and development. The company's team of highly skilled engineers and scientists work tirelessly to improve the performance and efficacy of their perforation systems. Through extensive testing and simulations, they ensure that each product meets the highest standards of quality and reliability, thus providing optimal results for their clients.Perforation Productivity's flagship product, the [product name], has gained widespread recognition and acclaim within the industry. Designed with state-of-the-art technology, this revolutionary perforation system offers superior performance, delivering enhanced well productivity and increased hydrocarbon recovery.The [product name] is equipped with a unique design that enables precise and controlled perforation of wellbores. With its advanced materials and engineering, it ensures minimal damage to the surrounding formation, allowing for improved hydraulic fracturing operations and reservoir stimulation. This leads to higher flow rates, reduced well downtime, and ultimately, a significant increase in overall well productivity.Moreover, Perforation Productivity's perforation systems are designed to be compatible with a wide range of well types, including vertical, deviated, and horizontal wells. This versatility makes them suitable for various reservoir conditions and extraction processes, catering to the diverse needs of the industry.In addition to their exceptional product offerings, Perforation Productivity places great emphasis on customer satisfaction. The company works closely with its clients to understand their specific requirements and challenges, providing tailored solutions that address their unique needs. This customer-centric approach has earned Perforation Productivity a loyal and expanding customer base, establishing the company as a trusted partner in the oil and gas sector.As sustainability and environmental awareness become increasingly important in the industry, Perforation Productivity is also committed to developing perforation systems that minimize environmental impact. Their products are designed to reduce waste and maximize efficiency, ensuring responsible resource extraction while adhering to stringent environmental regulations.Perforation Productivity's dedication to innovation and excellence has not gone unnoticed. The company has been recognized with several industry awards, testament to their contributions in advancing the oil and gas sector. Their commitment to research and development sets them apart from competitors, making them a preferred choice for clients seeking cutting-edge solutions.Looking ahead, Perforation Productivity remains focused on further advancements in perforation technology. The company continues to invest in research and development, exploring new materials, designs, and methodologies to further enhance well productivity, reduce costs, and minimize environmental impact.As the oil and gas industry faces evolving challenges, Perforation Productivity is well-positioned to lead the way with its innovative solutions. By constantly pushing the boundaries of technology and efficiency, the company is revolutionizing the industry and shaping the future of oil and gas extraction. With Perforation Productivity's perforation systems, the potential for increased productivity and profitability in the sector is tremendous.