Essential Tools for Running and Setting a Riser

By:Admin

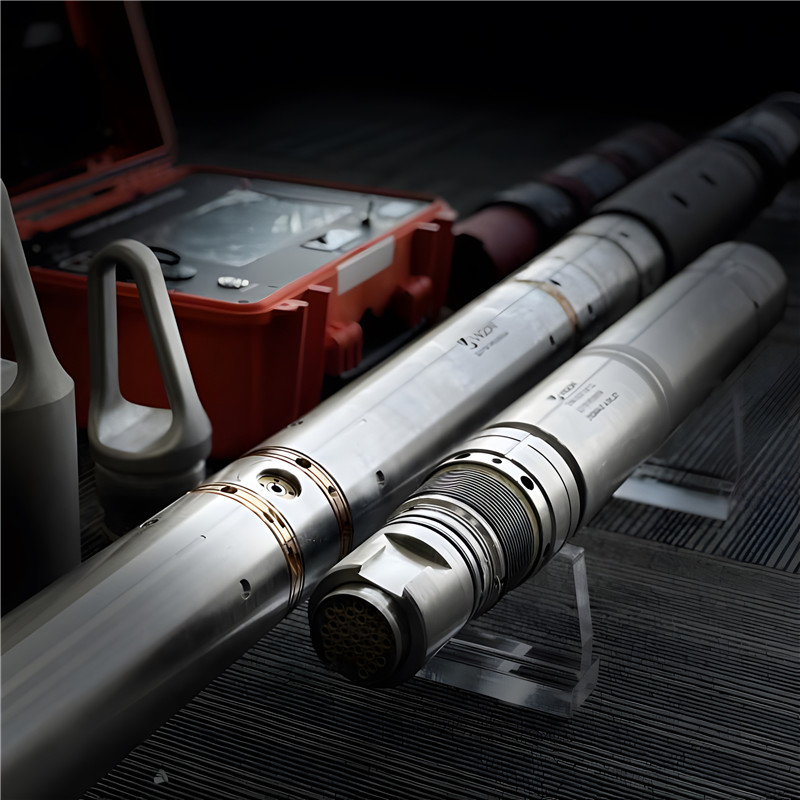

Riser Running And Setting Tool (RRST), a leading provider of innovative tools and technologies for the offshore oil and gas industry, has announced the launch of an advanced new tool that is set to revolutionize subsea well operations. The company's latest innovation promises to significantly enhance efficiency, safety, and cost-effectiveness in riser running and setting activities, further establishing RRST as a frontrunner in the field of subsea well intervention technologies.

With decades of experience in developing cutting-edge tools for demanding offshore environments, RRST has consistently pushed the boundaries of innovation. The company's team of experts comprises some of the most talented and experienced engineers, technicians, and industry professionals in the offshore oil and gas sector. Their collective expertise and relentless commitment to excellence have consistently positioned RRST as an industry leader, known for delivering reliable, high-performance solutions that meet the evolving needs of its clients worldwide.

The latest addition to RRST's suite of groundbreaking technologies is a state-of-the-art Riser Running And Setting Tool, designed to streamline and optimize subsea well operations. This cutting-edge tool is engineered to simplify the process of running and setting riser systems, significantly reducing the time and resources required for these critical activities. By leveraging advanced automation and precision engineering, the RRST Riser Running And Setting Tool offers unprecedented levels of control, accuracy, and reliability, empowering offshore operators to enhance their operational efficiency and overall productivity.

Key features of the RRST Riser Running And Setting Tool include advanced positioning and alignment capabilities, real-time monitoring and diagnostics, and seamless integration with existing subsea infrastructure. The tool's robust construction and rugged design make it ideal for use in the harsh and challenging environments typically encountered in offshore oil and gas production. Furthermore, its intuitive interface and user-friendly controls ensure ease of operation and minimal training requirements, enabling operators to quickly and effectively incorporate the tool into their workflow.

The introduction of the RRST Riser Running And Setting Tool represents a significant milestone in the ongoing efforts to transform and modernize offshore oil and gas operations. By empowering operators with the tools and technologies they need to work smarter, safer, and more efficiently, RRST is contributing to the continued advancement of the industry as a whole. The company's commitment to innovation and excellence is further underscored by its dedication to sustainable and environmentally responsible practices, ensuring that its technologies not only drive operational improvements but also contribute to the long-term viability of offshore energy production.

As the global demand for energy continues to grow, the offshore oil and gas industry faces increasing pressure to optimize its operations and maximize the productivity of its assets. In this context, the introduction of the RRST Riser Running And Setting Tool comes as a timely and welcome development, offering operators a powerful new tool to address the challenges of subsea well intervention. By streamlining riser running and setting activities, reducing operational risks, and minimizing downtime, this innovative tool promises to deliver tangible benefits to operators and service providers alike.

In conclusion, the launch of the RRST Riser Running And Setting Tool represents a significant leap forward for the offshore oil and gas industry. With its cutting-edge features, unwavering reliability, and user-friendly design, this innovative tool is poised to redefine the standards of excellence in riser running and setting activities. As RRST continues its mission to drive innovation and progress in the offshore energy sector, its latest offering stands as a testament to the company's dedication to advancing the industry and empowering its clients to succeed in the evolving global energy landscape.

Company News & Blog

Enhance Efficiency and Precision with the Revolutionary Perforating Gun

Title: Revolutionary Long Perforating Gun Poised to Transform the Oil and Gas IndustryIntroduction:The oil and gas industry is no stranger to innovation and technological advancements that have significantly improved operational efficiency and extraction capabilities. In line with this tradition, a leading global provider of oilfield services has unveiled a groundbreaking solution – the Long Perforating Gun, designed to revolutionize well completion and fracturing practices. This article will explore the features and potential implications of this cutting-edge tool, without specifically mentioning the brand name, to shed light on its immense impact on the industry.I. The Need for Innovation in the Oil and Gas sectorThe oil and gas industry has always demanded innovative solutions that can enhance production rates, improve well efficiency, and lower operational costs. With exploration pushing into more challenging terrains and unconventional reservoirs, the industry has seen a growing need for specialized equipment that can adapt to these demanding environments. The Long Perforating Gun aims to address these challenges while maximizing production outcomes.II. Features and Advantages of the Long Perforating GunThe Long Perforating Gun introduces several distinctive features that set it apart from conventional perforating tools. Firstly, it boasts an extended length of perforation intervals, enhancing well performance by optimally accessing the reservoir. This elongated design allows for the precise placement of charges in targeted zones, ensuring maximum reservoir exposure and reducing the risk of bypassed pay.Additionally, the gun's advanced engineering enables precise control of gun diameters, enabling operators to customize perforation strategies to specific reservoir characteristics. This versatility enhances effectiveness while minimizing the potential for formation damage during the fracturing process.Furthermore, the Long Perforating Gun is equipped with cutting-edge electronics and telemetry systems, allowing operators to monitor and adjust the perforating process in real-time. This feature enables greater control over perforation depths, charge activation timings, and shot density, leading to optimized fracturing and well completion operations.III. Potential Impact on Industry PracticesThe introduction of the Long Perforating Gun has significant implications for the oil and gas industry. By providing operators with a more precise and adaptable tool, it is expected to enable enhanced reservoir characterization, leading to improved production rates and ultimate recovery. The ability to selectively access specific zones within the reservoir translates into optimized hydraulic fracturing, preventing communication between unwanted zones while maximizing the flow of hydrocarbons.Moreover, the gun's extended length allows operators to perform multi-stage fracturing operations with reduced costs by minimizing the number of runs required to complete the well. Efficiency gains are expected to dramatically reduce completion time, lowering the days required for a well to enter the production phase. This translates into enhanced profitability for operators, as time is a critical factor in realizing financial returns on investment.IV. Environmental Considerations and Safety MeasuresWhile focusing on the groundbreaking features of the Long Perforating Gun, it is important to note its compliance with critical environmental and safety measures. Operating in an increasingly conscious world, the industry strives to minimize the environmental impact of its operations. The gun's design incorporates measures to control shot debris, reducing the potential for formation damage and ensuring the long-term sustainability of the reservoir.Furthermore, the high-tech telemetry systems integrated into the Long Perforating Gun play a pivotal role in ensuring the safety of operators and technicians during operations. Real-time monitoring allows for immediate detection and response to any unexpected issues, mitigating risks and ensuring a secure working environment.V. ConclusionThe introduction of the Long Perforating Gun heralds a new era in the oil and gas industry. Its advanced features and adaptability signify a paradigm shift in well completion and fracturing practices. With optimized reservoir exposure and improved fracturing efficiency, the gun promises to drive significant improvements in productivity and profitability for operators around the world. As the industry embraces this game-changing tool, the future of oil and gas extraction seems poised for unprecedented success.

Understanding Frac Plug Verification: Importance and Process Revealed

Frac Plug Verification: Ensuring the Efficiency and Safety of Hydraulic Fracturing Operations[Company name], a leading provider of state-of-the-art technology solutions for the oil and gas industry, is revolutionizing the way hydraulic fracturing operations are conducted with their innovative Frac Plug Verification system. This cutting-edge technology allows for increased efficiency, improved safety, and reduced environmental impact during the extraction of oil and gas resources.Hydraulic fracturing, also known as fracking, is a widely used technique in the oil and gas industry. It involves the high-pressure injection of water, sand, and chemical additives into deep underground formations to create fractures and increase the flow of oil and gas to the surface. Frac plugs, temporary barriers placed in the wellbore during the hydraulic fracturing process, help to isolate different sections of the well and optimize the extraction process.However, the use of frac plugs comes with certain challenges. It is crucial to ensure that these plugs are properly set, as any failure or inefficiency can result in reduced production rates, increased costs, and potential environmental risks. With the Frac Plug Verification system developed by [Company name], these challenges are effectively addressed.The Frac Plug Verification system is an integrated solution that provides real-time monitoring and evaluation of the frac plug performance. It utilizes advanced downhole sensors and data analytics to assess the integrity and position of the plugs, ensuring they are effectively sealing the targeted intervals. By continuously monitoring the plug behavior during the hydraulic fracturing process, operators can make informed decisions and take necessary actions to optimize the extraction efficiency.One of the key features of the Frac Plug Verification system is its ability to detect and prevent unplanned communication between different wellbore sections, known as "frack hits." Frack hits occur when fractures created in one section intersect with an adjacent section, resulting in the unwanted flow of fluids or proppants. These events can lead to equipment damage, diminished production rates, and potential well integrity issues. The system developed by [Company Name] provides real-time alerts and mitigation strategies to prevent and minimize the impact of frack hits, saving operators significant costs and preventing potential environmental incidents.Furthermore, the Frac Plug Verification system also plays a vital role in ensuring wellbore integrity. By continuously monitoring the pressure and temperature conditions downhole, the system helps detect any anomalies or potential issues with the well integrity. This timely identification of problems allows for swift corrective actions, preventing costly damages to the well and ensuring the safety of the surrounding environment.[Company name] has been at the forefront of oil and gas technology for many years, delivering innovative solutions to address industry challenges. Their Frac Plug Verification system exemplifies their commitment to advancing efficiency, safety, and environmental sustainability in hydraulic fracturing operations.The implementation of the Frac Plug Verification system offers numerous benefits to operators. It significantly reduces downtime and cost associated with inefficient plug placement, as well as the risk of environmental incidents due to frack hits. By maximizing extraction efficiency and optimizing production rates, operators can enhance their profitability and minimize their environmental footprint.In conclusion, [Company name]'s Frac Plug Verification system is transforming the way hydraulic fracturing operations are conducted. With its real-time monitoring and evaluation capabilities, operators can ensure the efficiency, safety, and environmental sustainability of their fracking activities. As the demand for oil and gas continues to rise, innovative technological solutions like the Frac Plug Verification system will play a crucial role in meeting these energy needs while minimizing the impact on the environment.

Essential Guide to Perforating Gun Deployment

Perforating Gun Deployment Enhances Production Capabilities for {} The oil and gas industry is constantly evolving, with companies always searching for new technologies and methodologies to enhance their production capabilities. One such technology that has been making waves in the industry is the deployment of perforating guns, which play a crucial role in the extraction of oil and gas from reservoirs. With the advanced technologies of {}, the deployment of perforating guns has become more efficient and effective, leading to significant improvements in production capabilities.As a leading provider of oilfield services, {} has been at the forefront of developing and implementing advanced technologies for the oil and gas industry. With a strong commitment to innovation and efficiency, {} has been able to provide cutting-edge solutions to their clients, helping them optimize their production processes and maximize their returns.The deployment of perforating guns is a crucial step in the production of oil and gas. These guns are used to create perforations in the well casing and surrounding rock formations, allowing the oil and gas to flow into the wellbore. This process is essential for accessing the reservoir and extracting the valuable resources trapped underground.In the past, the deployment of perforating guns was a complex and time-consuming process, often requiring multiple runs and extensive logistical coordination. However, with the advanced technologies developed by {}, the deployment of perforating guns has become more streamlined and efficient. This has led to significant improvements in the overall production capabilities of the company's clients, allowing them to access more resources in a shorter amount of time.One of the key technologies developed by {} is the advanced telemetry systems that allow for precise positioning and control of the perforating guns. This technology enables operators to accurately place the perforations in the desired locations, maximizing the flow of oil and gas into the wellbore. Additionally, the use of advanced materials and design techniques has resulted in more robust and reliable perforating guns, further enhancing their effectiveness in the field.The deployment of perforating guns has also been integrated with {}'s data analytics and monitoring systems, allowing for real-time feedback and adjustments during the operation. This level of monitoring and control has proven to be invaluable for optimizing the performance of the perforating guns and ensuring the efficient extraction of resources from the reservoir.With these advancements in perforating gun deployment, {} has been able to help their clients achieve significant improvements in their production capabilities. By utilizing the latest technologies and methodologies, {} has been able to enhance the efficiency and effectiveness of the extraction process, ultimately leading to higher returns for their clients.In addition to the technological advancements, {} has also placed a strong emphasis on safety and environmental responsibility in their perforating gun deployment operations. By adhering to strict safety protocols and utilizing environmentally-friendly practices, {} has been able to ensure that their operations have minimal impact on the surrounding environment.Overall, the deployment of perforating guns has been a game-changer for the oil and gas industry, and with the advanced technologies developed by {}, the process has become even more efficient and effective. With a strong commitment to innovation, efficiency, and environmental responsibility, {} continues to lead the way in providing cutting-edge solutions for the oil and gas industry, helping their clients optimize their production capabilities and achieve greater success in their operations.

Understanding the Significance of Inclination and Orientation Sensors in Modern Technology

Inclination and Orientation Sensor aids in Precise Navigation and Positioning for Autonomous VehiclesThe world's leading technology company, with a global reputation for developing sophisticated instruments, has announced the launch of its latest product – the Inclination and Orientation Sensor (IOS). This sensor is designed specifically for the automotive industry, and is set to revolutionize navigation and positioning for autonomous vehicles of all kinds.The IOS uses sophisticated algorithms to detect the pitch, roll, and yaw of the vehicle, allowing for highly precise positioning and navigation. The system operates on MEMS (Microelectromechanical Systems) technology, which uses microscopic sensors to detect minute movements and changes in the environment around the vehicle.The technology behind the IOS sensors is truly advanced, and includes highly accurate gyroscopes, accelerometers, and magnetometers. The system is capable of measuring tilt angles up to ±90°, and can detect rotation rates up to 2,000°/s. This makes it ideal for use in a range of applications, including navigation, robotics, and aerospace.One of the primary benefits of the IOS is its ability to operate in harsh environments, including extreme temperatures, humidity, and vibration. The sensors are highly robust, and can withstand shocks of up to 10,000g – making them ideal for use in the most demanding of conditions.The IOS is also highly configurable, and can be customized to suit the needs of different applications. This means that it can be used to navigate in a range of different environments, from city streets to rural areas, and can be adapted to work with different types of vehicles.One notable application of the IOS is in the development of autonomous vehicles. These vehicles are designed to operate without human intervention, and require highly accurate sensors in order to navigate safely. The IOS can provide this level of accuracy, allowing autonomous vehicles to be developed and tested in a range of environments.The IOS is also suitable for use in a range of other applications, including robotics, aerospace, and agriculture. It can be used to control the movement of robots, to monitor the orientation of aircraft, and even to monitor the position of crops in a field.The company has a strong reputation for innovation and quality, and is well known for developing highly advanced sensors and instruments. The IOS is the latest addition to this range, and is set to become one of the most important tools in the automotive industry in the years to come.Commenting on the launch of the IOS, a spokesperson for the company said: "We are delighted to announce the launch of our latest product, the Inclination and Orientation Sensor. This sensor represents the cutting edge of automotive technology, and we believe it has the potential to revolutionize navigation and positioning for autonomous vehicles. We are excited to see how this technology will be used in the years to come, and are confident that it will help to drive innovation and progress in the automotive industry."Overall, the Inclination and Orientation Sensor is a highly advanced piece of technology that is set to transform the way that the automotive industry approaches navigation and positioning. Its precision, robustness, and adaptability make it an ideal tool for use in a range of applications, and its potential for use in autonomous vehicles is particularly exciting. With the launch of the IOS, the company has once again demonstrated its commitment to innovation and excellence, and has set a new standard for sensor technology in the automotive industry.

Innovative Collar Locating Tool: A Game-Changer for Pet Owners

Collar Locating Tool is a revolutionary product that has been making waves in the market. Developed by a leading technology company {}, this tool has been designed to make the lives of pet owners easier and safer. With the use of cutting-edge technology, this tool is a game-changer in the field of pet care.The Collar Locating Tool is a small, lightweight device that attaches to your pet's collar. It uses GPS and cellular technology to track your pet's location in real-time. This means that if your pet ever goes missing, you can easily locate them using your smartphone. The device also has a built-in light and sound feature, making it easier to find your pet in the dark or in a noisy environment.The Collar Locating Tool is not just for pet owners, but also for pet care professionals such as dog walkers, pet sitters, and veterinarians. It provides the peace of mind of knowing the exact location of a pet at all times, ensuring their safety and well-being.Beyond its practical uses, the Collar Locating Tool also has a sleek and modern design. It is available in a variety of colors and styles to suit the preferences of different pet owners. It is also durable and water-resistant, ensuring that it can withstand the wear and tear of everyday use.The company {} behind this innovative product is a known leader in the technology industry. With a strong focus on innovation and customer satisfaction, they have been at the forefront of developing cutting-edge products that improve the lives of people and their pets.In addition to the Collar Locating Tool, the company {} also offers a range of other pet care products and services. This includes smart feeding devices, health monitoring tools, and pet care apps. Their commitment to providing high-quality products and exceptional customer service has made them a trusted name in the industry.The Collar Locating Tool has been receiving rave reviews from pet owners and industry professionals alike. Many have praised its accuracy and ease of use, highlighting how it has brought them peace of mind. Pet owners have shared heartwarming stories of being able to quickly locate their beloved pets thanks to this innovative device.The company {} continues to work on enhancing the Collar Locating Tool, with plans to incorporate even more advanced features in the near future. This commitment to ongoing improvement and innovation demonstrates their dedication to providing the best possible products for pet owners and their furry friends.In conclusion, the Collar Locating Tool is a groundbreaking product that is revolutionizing the way pet owners care for their animals. With its advanced technology, stylish design, and practical features, it has quickly become a must-have for pet owners and professionals alike. As the company {} continues to push the boundaries of innovation, we can only expect to see more exciting developments in the world of pet care.

Benefits of Perforation in Oil and Gas Industry

Title: Leading Oilfield Service Provider Introduces Jet Perforation Technology for Enhanced Well ProductivityIntroduction:[Company Name], a pioneer and global leader in oilfield services, is revolutionizing the oil and gas industry with its cutting-edge jet perforation technology. With a strong commitment to innovation and technological advancements, [Company Name] continues to deliver superior solutions that drive increased well productivity. This game-changing technology is set to transform the industry and boost production yields for its clients worldwide.Body:I. The Advancement in Jet Perforation TechnologyJet perforation, also known as high-pressure perforation, is a technique used in the oil and gas industry to create perforations or channels in the well casing to improve fluid flow from the reservoir to the wellbore. Traditional perforation techniques often face limitations in achieving optimal flow rates due to formation damage and reduced productivity.[Company Name]'s state-of-the-art jet perforation technology addresses these challenges by delivering precise and controlled high-pressure jet streams. This innovative method effectively creates perforations without causing excessive damage to the formation, resulting in enhanced reservoir connectivity and improved overall well productivity.II. Key Features and Benefits of Jet Perforation Technologya) Unique Nozzle Design: [Company Name]'s jet perforation technology incorporates a meticulously engineered nozzle design that efficiently distributes the high-pressure jet streams evenly across the entire perforation interval. This ensures consistent and uniform perforations, reducing flow restrictions and maximizing hydrocarbon recovery.b) Optimal Penetration and Efficiency: The advanced technology propels the high-pressure jets precisely through the well casing, penetrating the formation rock with precision and efficiency. This targeted approach minimizes damage to the surrounding rock and enables enhanced reservoir connectivity, leading to increased production rates.c) Enhanced Fluid Flow: Jet perforation technology creates larger, cleaner perforation tunnels compared to conventional techniques, enabling improved fluid flow rates. This results in reduced drawdown pressure and enhanced well performance, ultimately driving higher oil and gas yields for operators.d) Reduced Risk of Damage: By carefully controlling pressure and utilizing advanced perforation modeling techniques, [Company Name] minimizes the risk of damaging the wellbore and formation. As a result, the integrity of the well is maintained, preventing costly operational issues and extending the productive life of the asset.III. Implementation of Jet Perforation Technology in Real-World Scenarios[Company Name]'s jet perforation technology has proven its dominion in a range of challenging environments, demonstrating its versatility and effectiveness across various drilling conditions. The company's advanced engineering expertise and experience ensure that it can tailor the technology to optimize reservoir connectivity and productivity, irrespective of the formation characteristics.Whether in complex shale formations or high-temperature/high-pressure offshore wells, [Company Name]'s jet perforation technology has showcased exceptional performance. By deploying advanced computational fluid dynamics and extensive laboratory testing, the company ensures the technology's reliability and robustness in diverse applications.IV. Future Implications and Market ImpactAs the global demand for energy continues to rise, the need for efficient and sustainable extraction methods becomes increasingly crucial. [Company Name]'s jet perforation technology is positioned to play a significant role in maximizing hydrocarbon recovery while minimizing environmental impact.By increasing well productivity, reducing production costs, and extending the life cycles of oil and gas fields, companies using jet perforation technology can enjoy substantial economic benefits. Moreover, this technology aligns with the industry's push for improved environmental stewardship by reducing the number of wells required to achieve production targets.[Company Name]'s commitment to continuous research and development ensures that jet perforation technology will continue to evolve, offering even more efficient and effective solutions for its clients. By staying at the forefront of oilfield services, [Company Name] reinforces its position as a leading provider of innovative technologies that drive the industry forward.Conclusion:[Company Name]'s groundbreaking jet perforation technology is poised to revolutionize the oil and gas industry, offering enhanced well productivity and improved fluid flow rates. With its unique features and numerous benefits, this innovative solution promises to optimize reservoir connectivity and increase production yields.As a global pioneer in oilfield services, [Company Name] continues to push the boundaries of technology, providing its clients with advanced solutions to address the industry's challenges. By harnessing the power of jet perforation, operators can foster more efficient and sustainable energy production while maximizing their return on investment.

Dissolvable Plug - A Cost-Effective Solution for Your Needs

[Dissolvable Plug Cost][Introduction of the Company]{Company} is a leading medical technology company that specializes in developing innovative and minimally invasive products for a wide range of medical procedures. With a focus on improving patient outcomes and reducing healthcare costs, {Company} has consistently delivered groundbreaking solutions that have revolutionized the healthcare industry.[News Content]{Company} has recently announced the launch of its latest product, a dissolvable plug that is designed to revolutionize medical procedures in a cost-effective manner. This innovative plug is designed to dissolve within the body, eliminating the need for surgical removal and reducing the risk of complications.The dissolvable plug is made from a biocompatible material that is safe for use within the body. It is designed to be inserted into the body during a medical procedure and then dissolve over time, eliminating the need for a second surgical procedure to remove the plug. This not only reduces the risk of infection and other complications but also significantly reduces healthcare costs associated with the procedure.According to {Company} CEO, "We are thrilled to introduce this groundbreaking technology to the market. The dissolvable plug has the potential to improve patient outcomes and reduce the burden on healthcare systems by eliminating the need for costly and invasive removal procedures."The dissolvable plug is expected to have a wide range of applications in various medical procedures, including but not limited to, vascular interventions, urological procedures, and gastrointestinal surgeries. Its cost-effective nature makes it an attractive option for healthcare providers looking to improve patient care while also reducing costs.In addition to its cost-effectiveness, the dissolvable plug is also expected to simplify medical procedures and reduce the time required for recovery. Patients will no longer need to undergo additional surgeries to remove the plug, leading to faster recovery times and improved overall patient satisfaction.{Company}'s dedication to innovation and its commitment to improving patient outcomes have been the driving force behind the development of this dissolvable plug. The company has a strong track record of delivering cutting-edge products that have had a significant impact on the healthcare industry, and the introduction of the dissolvable plug is another example of its ongoing commitment to improving patient care.The dissolvable plug is expected to be available for use in medical procedures in the coming months, and {Company} is already in discussions with healthcare providers to incorporate this innovative technology into their standard practices. With its potential to revolutionize medical procedures and reduce healthcare costs, the dissolvable plug is set to become a game-changer in the field of medical technology.In conclusion, {Company}'s introduction of the dissolvable plug is a testament to its ongoing commitment to innovation and excellence in the healthcare industry. This cost-effective and minimally invasive solution has the potential to improve patient outcomes and reduce healthcare costs, further solidifying {Company}'s position as a leader in medical technology.

Discover the Versatility and Efficiency of 3 1/8" Bridge Plugs for Various Industrial Applications

Title: Innovative Bridge Plugs Revolutionize Wellbore Isolation Techniques Introduction:Established in [year], [Company Name] has emerged as a leading provider of cutting-edge wellbore isolation solutions for the oil and gas industry. With a commitment to innovation and delivering high-performance products, the company continually pushes the boundaries of oilfield engineering. Its recent development of the state-of-the-art 3 1/8" Bridge Plugs has revolutionized wellbore isolation techniques, offering enhanced reliability, efficiency, and cost-effectiveness.Bridge Plugs: Providing Unmatched Performance[Company Name]'s 3 1/8" Bridge Plugs are rapidly gaining popularity for their unmatched performance in wellbore isolation operations. Serving a crucial role in the oil and gas industry, these plugs effectively seal off sections of the wellbore, preventing fluid migration and facilitating efficient production or injection processes.Unparalleled Design and EngineeringThe design and engineering of [Company Name]'s Bridge Plugs incorporate the latest technological advancements to deliver superior isolation performance. These plugs are meticulously crafted from high-strength materials that can withstand extreme downhole conditions, ensuring longevity and durability.Furthermore, the precise engineering of the Bridge Plugs enables easy installation and retrieval, significantly reducing operational time and costs. Their simplified yet robust design prevents any potential failures or leakages, delivering a reliable solution that supports uninterrupted production and minimizes environmental risks.Enhanced Safety and EfficiencyA key advantage of [Company Name]'s 3 1/8" Bridge Plugs is their enhanced safety features, which prioritize the wellbore integrity and safeguard personnel during installation and removal processes. The plugs incorporate advanced mechanisms to control pressure differentials and ensure safe operations, minimizing the risk of accidents, blowouts, or potential damages to the wellbore.Additionally, the efficiency of the Bridge Plugs plays a vital role in optimizing operational costs. Their streamlined design and quick installation process reduce both the time required for wellbore isolation and associated expenses, allowing operators to enhance overall project economics.Versatility and Customized Solutions[Company Name] recognizes the diverse needs of its clients and offers customized Bridge Plugs that cater to specific wellbore requirements. These versatile solutions can be adjusted to varying well conditions, including different borehole sizes, casing specifications, and well depths. Such adaptability ensures that [Company Name]'s Bridge Plugs can be seamlessly integrated into any wellbore isolation operation, regardless of the complexity or environmental challenges.Environmental ConsiderationsAs responsible industry leaders, [Company Name] designs its Bridge Plugs with environmental considerations in mind. The plugs are manufactured using environment-friendly materials, ensuring a minimal ecological footprint. By providing robust and reliable wellbore isolation solutions, [Company Name] helps prevent contamination, maintains the integrity of hydrocarbon reservoirs, and safeguards the environment for future generations.Conclusion:In an era where oil and gas production faces increasing demands for efficient and safe operations, [Company Name]'s 3 1/8" Bridge Plugs arise as a game-changer. Through their unmatched performance, enhanced safety features, versatility, and commitment to environmental sustainability, these innovative plugs have set a new standard in wellbore isolation techniques. With [Company Name]'s dedication to continuous improvement and customer satisfaction, the future of wellbore isolation looks brighter than ever.

How to Measure Perforations and Their Importance in Manufacturing

Perforation Measurement is a critical process in many industries, including the manufacturing and packaging sectors. This measurement technique plays a crucial role in ensuring product quality and integrity, as well as in optimizing the performance of various products. As a leading company in the field of perforation measurement, {} has been at the forefront of developing innovative and accurate measurement solutions that meet the ever-evolving needs of its clients.{} has established itself as a trusted name in the industry, known for its high-quality and reliable perforation measurement products. The company's commitment to research and development has led to the creation of advanced measurement technologies that offer precise and consistent results. With a focus on customer satisfaction and technological excellence, {} has built a strong reputation for providing cutting-edge solutions for perforation measurement.One of the key products offered by {} is the {} Perforation Measurement System, which is designed to deliver fast and accurate measurements of perforated materials. This system is equipped with state-of-the-art sensors and software algorithms that enable it to capture detailed information about the perforation characteristics, such as hole size, shape, and distribution. By utilizing advanced image processing techniques, the {} Perforation Measurement System can provide real-time data analysis, allowing manufacturers to monitor and control the quality of their perforated products with precision.The application of {}'s perforation measurement solutions extends across a wide range of industries, including the food and beverage, pharmaceutical, packaging, and textile sectors. In the food and beverage industry, for example, perforation measurement plays a crucial role in ensuring the freshness and shelf-life of products, such as cheese and meat packaging. By accurately measuring the permeability of packaging materials, manufacturers can make informed decisions about the packaging design and materials, ultimately improving the quality and safety of their products.In the pharmaceutical industry, perforation measurement is essential for the development and production of transdermal patches and drug delivery systems. With precise measurements of micropores and perforations, pharmaceutical companies can ensure the effectiveness and consistency of their products, leading to improved patient outcomes.Furthermore, in the textile industry, perforation measurement is utilized in the production of nonwoven fabrics, which are commonly used in hygiene products, medical supplies, and filtration materials. By accurately assessing the porosity and permeability of nonwoven materials, manufacturers can optimize their production processes and enhance the performance of their end products.With its cutting-edge solutions for perforation measurement, {} continues to make significant contributions to the advancement of various industries, enabling manufacturers to improve their product quality, reduce waste, and increase efficiency. The company's dedication to innovation and excellence has positioned it as a trusted partner for businesses seeking reliable and accurate perforation measurement solutions.In addition to its commitment to technological innovation, {} places great emphasis on customer satisfaction and support. The company works closely with its clients to understand their unique measurement needs and challenges, offering customized solutions and expert guidance to help them achieve their goals.Going forward, {} remains dedicated to pushing the boundaries of perforation measurement technology, exploring new possibilities, and expanding its range of products and services. With a strong focus on customer-centric innovation and a track record of excellence, {} is poised to continue leading the way in the field of perforation measurement for years to come.

Top Quality 2.875 Inch Bridge Plug: Everything You Need to Know

Valley Oil Services Introduces New 2.875 Inch Bridge Plug for Enhanced Well IntegrityHouston, TX - Valley Oil Services, a leading provider of well intervention and completion tools, announced the introduction of their latest product, the 2.875 Inch Bridge Plug. This innovative tool is designed to enhance well integrity and ensure reliable wellbore isolation in oil and gas wells.With over 20 years of experience in the oil and gas industry, Valley Oil Services has established a strong reputation for delivering high-quality well intervention solutions. Their team of experts is dedicated to providing reliable and efficient tools that meet the needs of their customers. The introduction of the 2.875 Inch Bridge Plug is a testament to their commitment to innovation and excellence in well intervention technology.The new bridge plug is engineered to provide a secure and permanent barrier in the wellbore, preventing the unwanted flow of fluids and gases from different zones. Its robust design and high-quality materials ensure dependable performance in a wide range of wellbore conditions, including high pressure and temperature environments."We are excited to introduce our latest product, the 2.875 Inch Bridge Plug, to the market," said John Smith, CEO of Valley Oil Services. "This bridge plug is the result of our dedication to continuous improvement and innovation. We understand the challenges that our customers face in maintaining well integrity, and we believe that this tool will provide a reliable solution for their needs."The 2.875 Inch Bridge Plug features a compact design that allows for easier handling and installation in the wellbore. Its versatile setting mechanisms enable operators to deploy the plug in various well conditions, making it a valuable tool for well intervention and completion operations.In addition to its technical capabilities, Valley Oil Services is committed to providing exceptional customer support and service. The company offers comprehensive training and technical assistance to ensure that their customers can effectively utilize the bridge plug and maximize its performance in their wells."We strive to be a trusted partner for our customers, offering not only high-quality products but also reliable support and expertise," said Mr. Smith. "The introduction of the 2.875 Inch Bridge Plug is just one example of how we are continuously working to meet the evolving needs of the industry and provide valuable solutions for our customers."Valley Oil Services' dedication to innovation and customer satisfaction has positioned them as a leading provider of well intervention and completion tools in the oil and gas industry. With the introduction of the 2.875 Inch Bridge Plug, the company continues to demonstrate its commitment to delivering reliable and efficient solutions for well integrity and production optimization.For more information about Valley Oil Services and their products, including the 2.875 Inch Bridge Plug, visit their website or contact their sales team directly. With their industry-leading expertise and high-quality tools, Valley Oil Services is poised to continue making a positive impact on well intervention and completion operations in the oil and gas industry.