Maximizing Frac Plug Performance: Key Factors to Consider

By:Admin

The oil and gas industry is constantly evolving with new technologies and innovations that aim to make operations more efficient and cost-effective. One such innovation that has been making waves in the industry is the introduction of high-performance frac plugs.

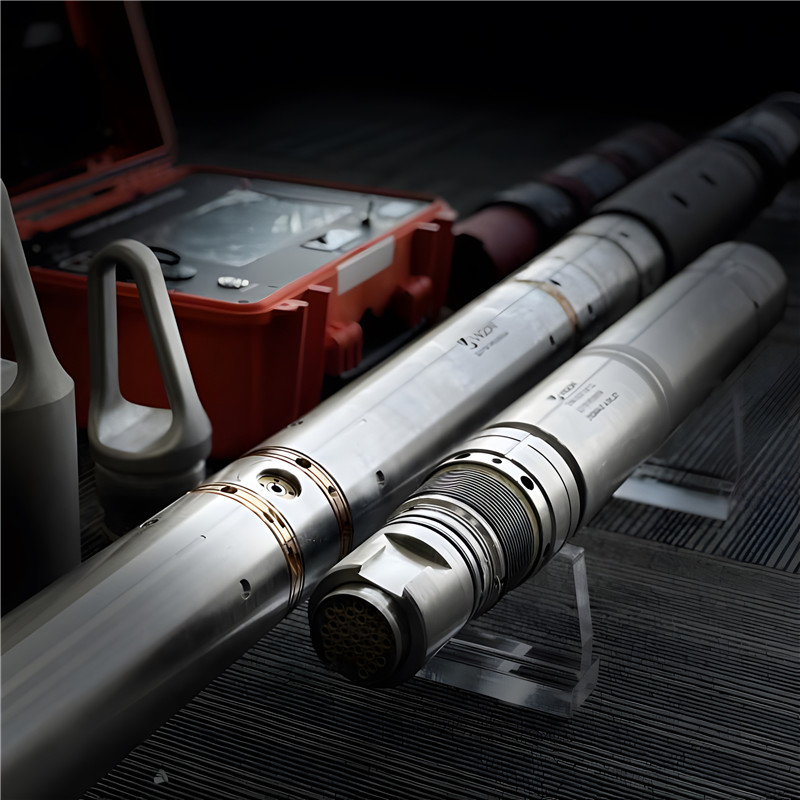

Frac plugs are used in the hydraulic fracturing process to isolate sections of the wellbore and create multiple fracture stages. They play a crucial role in the success of hydraulic fracturing operations, as they need to withstand extreme pressure and temperature conditions while effectively isolating different sections of the wellbore.

One company that has been at the forefront of developing high-performance frac plugs is {Company Name}. Their frac plugs have been gaining attention in the industry for their exceptional performance and reliability, making them a game changer for oil and gas operators.

{Company Name} is a leading provider of oilfield services and equipment, with a strong focus on delivering innovative solutions to enhance the efficiency and productivity of oil and gas operations. Their frac plugs are designed to address the challenges and limitations of traditional frac plugs, offering superior performance and durability.

The key features that set {Company Name}'s frac plugs apart from the competition include their robust design, advanced materials, and precision engineering. These frac plugs are engineered to withstand extreme downhole conditions, including high pressures and temperatures, while maintaining their integrity and effectiveness.

Furthermore, {Company Name}'s frac plugs are designed for easy and reliable deployment, minimizing the risk of operational delays and reducing overall costs. Their innovative design allows for efficient milling and retrieval, resulting in faster completion times and improved operational efficiency.

In addition to their exceptional performance, {Company Name}'s frac plugs are also designed with environmental considerations in mind. The company places a strong emphasis on sustainability and minimizing environmental impact, and their frac plugs are engineered to reduce waste and improve overall wellbore integrity.

The success of {Company Name}'s frac plugs can be attributed to their commitment to research and development, as well as their collaborative approach with oil and gas operators. By working closely with their customers, {Company Name} has been able to understand their specific challenges and develop tailored solutions to address their needs.

The impact of {Company Name}'s high-performance frac plugs has been significant in the oil and gas industry. Operators have reported improved well productivity, reduced operational costs, and enhanced overall efficiency of hydraulic fracturing operations. As a result, {Company Name} has established a strong reputation as a trusted provider of frac plug solutions.

Looking ahead, {Company Name} continues to innovate and develop new technologies to further enhance the performance and reliability of their frac plugs. Their dedication to continuous improvement and customer-driven solutions positions them as a leading player in the oil and gas industry.

In conclusion, {Company Name}'s high-performance frac plugs have proven to be a game changer for the oil and gas industry. Their innovative design, superior performance, and environmental considerations have set a new standard for frac plug technology, and their impact on hydraulic fracturing operations has been nothing short of transformative. As the industry continues to evolve, {Company Name} remains committed to driving innovation and delivering solutions that meet the evolving needs of oil and gas operators.

Company News & Blog

Maximizing Frac Plug Performance: Key Factors to Consider

Frac Plug Performance - a Game Changer in the Oil and Gas IndustryThe oil and gas industry is constantly evolving with new technologies and innovations that aim to make operations more efficient and cost-effective. One such innovation that has been making waves in the industry is the introduction of high-performance frac plugs.Frac plugs are used in the hydraulic fracturing process to isolate sections of the wellbore and create multiple fracture stages. They play a crucial role in the success of hydraulic fracturing operations, as they need to withstand extreme pressure and temperature conditions while effectively isolating different sections of the wellbore.One company that has been at the forefront of developing high-performance frac plugs is {Company Name}. Their frac plugs have been gaining attention in the industry for their exceptional performance and reliability, making them a game changer for oil and gas operators.{Company Name} is a leading provider of oilfield services and equipment, with a strong focus on delivering innovative solutions to enhance the efficiency and productivity of oil and gas operations. Their frac plugs are designed to address the challenges and limitations of traditional frac plugs, offering superior performance and durability.The key features that set {Company Name}'s frac plugs apart from the competition include their robust design, advanced materials, and precision engineering. These frac plugs are engineered to withstand extreme downhole conditions, including high pressures and temperatures, while maintaining their integrity and effectiveness.Furthermore, {Company Name}'s frac plugs are designed for easy and reliable deployment, minimizing the risk of operational delays and reducing overall costs. Their innovative design allows for efficient milling and retrieval, resulting in faster completion times and improved operational efficiency.In addition to their exceptional performance, {Company Name}'s frac plugs are also designed with environmental considerations in mind. The company places a strong emphasis on sustainability and minimizing environmental impact, and their frac plugs are engineered to reduce waste and improve overall wellbore integrity.The success of {Company Name}'s frac plugs can be attributed to their commitment to research and development, as well as their collaborative approach with oil and gas operators. By working closely with their customers, {Company Name} has been able to understand their specific challenges and develop tailored solutions to address their needs.The impact of {Company Name}'s high-performance frac plugs has been significant in the oil and gas industry. Operators have reported improved well productivity, reduced operational costs, and enhanced overall efficiency of hydraulic fracturing operations. As a result, {Company Name} has established a strong reputation as a trusted provider of frac plug solutions.Looking ahead, {Company Name} continues to innovate and develop new technologies to further enhance the performance and reliability of their frac plugs. Their dedication to continuous improvement and customer-driven solutions positions them as a leading player in the oil and gas industry.In conclusion, {Company Name}'s high-performance frac plugs have proven to be a game changer for the oil and gas industry. Their innovative design, superior performance, and environmental considerations have set a new standard for frac plug technology, and their impact on hydraulic fracturing operations has been nothing short of transformative. As the industry continues to evolve, {Company Name} remains committed to driving innovation and delivering solutions that meet the evolving needs of oil and gas operators.

Boost Your Website's Traffic with Effective Content Circulation and Bypass Control Strategies

Title: New Innovation in Circulation and Bypass Control Enhances Efficiency and Safety in IndustriesIntroduction: In today's rapidly evolving industrial landscape, companies are constantly seeking innovative solutions to optimize operations and improve safety standards. One such breakthrough has emerged in the form of Circulation and Bypass Control systems, developed by a leading technology company {}.Paragraph 1: Overview of Circulation and Bypass Control SystemsCirculation and Bypass Control systems serve as critical elements in various industries including oil and gas, chemical manufacturing, and water treatment facilities. These systems enable efficient circulation of fluids by maintaining consistent pressure and controlling the flow of liquid through pipelines and conduits.The integration of cutting-edge technology, state-of-the-art sensors, and advanced control mechanisms ensures optimal performance, enhances safety, and significantly reduces downtime and maintenance costs. By regulating flow rates, pressures, and valves, Circulation and Bypass Control systems facilitate seamless operations and prevent potential hazards.Paragraph 2: Advantages of Circulation and Bypass Control SystemsA crucial advantage of Circulation and Bypass Control systems lies in their ability to maintain precise control over the fluid flow. This capability enhances production reliability and minimizes risks associated with variations in pressure and temperature.Moreover, these systems support operational flexibility by allowing operators to redirect the flow of fluids as required, without disrupting the overall process. This adaptability ensures timely maintenance, troubleshooting, and upgrades, all while maintaining uninterrupted production schedules.In addition, the real-time monitoring and automated control functionalities provided by Circulation and Bypass Control systems lead to improved accuracy and efficiency. This not only optimizes resource utilization but also reduces energy consumption, contributing to sustainable operations.Paragraph 3: Application in the Oil and Gas IndustryThe oil and gas industry is one of the primary beneficiaries of Circulation and Bypass Control systems. These systems play a crucial role in ensuring safe and efficient drilling operations, preventing unforeseen blowouts, and maintaining the integrity of the wellbore.By monitoring and regulating fluid circulation in drilling and well-completion processes, Circulation and Bypass Control systems allow for accurate data acquisition, wellbore stability, and efficient operation control. This technology helps prevent potential hazards such as formation damage, fluid loss, and stuck pipe incidents.Furthermore, the application of Circulation and Bypass Control systems in oil and gas production facilities ensures the safe and controlled delivery of resources, maximizing production output while minimizing environmental risks.Paragraph 4: Advancements in Water Treatment FacilitiesWater treatment plants also benefit significantly from Circulation and Bypass Control systems. These systems enhance the efficiency of various water treatment processes, including filtration, disinfection, and desalination.By regulating the flow rate and pressure of water in treatment facilities, these systems provide optimized conditions for effective filtration and separation of contaminants. They also enable precise and automated control of chemical dosing, ensuring accurate and consistent water quality.Additionally, the remote monitoring capabilities of Circulation and Bypass Control systems allow operators to detect anomalies promptly, facilitating preventive maintenance and reducing downtime. This ultimately leads to improved water treatment efficiency and higher reliability in meeting quality standards.Paragraph 5: Future Trends and ConclusionAs industrial technologies continue to advance, Circulation and Bypass Control systems are likely to evolve further, incorporating advanced features such as artificial intelligence and predictive analytics. These advancements will enable predictive maintenance, real-time optimization, and improved safety standards across various industries.With their ability to enhance operational efficiency, ensure consistent control, and mitigate risks, Circulation and Bypass Control systems have revolutionized production processes in the oil and gas industry, water treatment facilities, and beyond. As companies strive for greater efficiency, productivity, and safety, these innovative systems are poised to play a vital role in shaping the industrial landscape moving forward.(Note: Brand name placeholders can be replaced with appropriate industry-wide terminology.)

Improving the Quality of Perforating Gun Shots: A News Update

Perforating Gun Shot Quality Revolutionizes the Oil and Gas IndustryThe global demand for oil and gas continues to rise, and with it, the need for efficient and effective extraction methods. As drilling technology advances, so does the need for high-quality perforating guns, an essential tool in the industry. One company has stepped up to the challenge, revolutionizing the field with their innovative approach to perforation. Perforating guns are devices used in oil and gas wells to create holes in the casing, cement, and formation surrounding the wellbore. These holes provide pathways for oil and gas to flow into the wellbore, enabling efficient extraction. The quality and efficiency of perforation directly impact the production rates and overall profitability of oil and gas wells.Introducing (Company Name), a global leader in perforation technology that has been at the forefront of the industry for over a decade. With a strong commitment to research and development, (Company Name) has consistently delivered cutting-edge solutions to improve well productivity and enhance reservoir performance.One of the key factors that sets (Company Name) apart from its competitors is its relentless focus on perfection. The company understands that even the smallest inefficiencies in perforation can result in substantial losses in production. To address this challenge, (Company Name) has developed a state-of-the-art perforating gun that ensures consistent and precise perforations every time.The secret behind the unparalleled quality of (Company Name)'s perforating gun lies in their advanced engineering and manufacturing processes. Each component is carefully designed and manufactured to the highest industry standards, ensuring durability, reliability, and optimal performance. (Company Name)'s perforating guns are subjected to rigorous quality control measures to guarantee their flawless operation in the harshest downhole conditions.In addition to their exceptional design and manufacturing, (Company Name) also offers a comprehensive support system to its customers. Their team of highly skilled engineers and technicians is available around the clock to provide expert advice and troubleshooting, ensuring smooth operations and minimal downtime.Furthermore, (Company Name) is dedicated to reducing its environmental impact. They employ advanced technology and responsible manufacturing processes to minimize waste and promote sustainability. By investing in research and development, (Company Name) continuously seeks innovative ways to improve efficiency and reduce the carbon footprint associated with perforation operations.The impact of (Company Name)'s perforating gun on the oil and gas industry has been significant. By providing higher-quality perforations, their technology has led to increased production rates and improved well economics for companies worldwide. Oil and gas operators using (Company Name)'s perforating guns have reported significant cost savings and enhanced reservoir performance, reinforcing the company's reputation as an industry leader.Looking towards the future, (Company Name) remains committed to pushing the boundaries of perforation technology. Through ongoing research and development, they aim to introduce even more advanced solutions that cater to the evolving needs of the oil and gas industry. With their unwavering commitment to excellence, it is clear that (Company Name) will continue to shape the future of perforation, driving increased efficiency and productivity in oil and gas operations worldwide.In conclusion, (Company Name)'s perforating gun has revolutionized the oil and gas industry, providing superior quality and performance. With a focus on perfection, advanced engineering, and unparalleled customer support, (Company Name) has become the go-to choice for oil and gas operators around the world. As the demand for oil and gas extraction grows, (Company Name) is well-positioned to lead the industry with their innovative solutions and commitment to sustainability.

Discover the Efficiency and Safety of Gun Loading Tubes

Title: Versatile Gun Loading Tube Enhances Firearm EfficiencyIntroduction:In today's fast-paced world, advancements in technology continuously push the boundaries of innovation across various industries. The firearms industry is no exception, as it witnesses the introduction of a cutting-edge accessory: the Gun Loading Tube. Developed by a leading provider of firearm accessories, this innovative product promises to revolutionize the way we load firearms, enhancing efficiency and convenience for firearm enthusiasts and professionals alike.Revolutionizing Firearm Loading:Loading a firearm can be a time-consuming and labor-intensive process, particularly in high-pressure situations where every second counts. The Gun Loading Tube is designed to address this issue by offering an advanced loading mechanism that streamlines the process, enabling users to reload their firearms swiftly and with ease.The design of the Gun Loading Tube is sleek and ergonomically friendly. It features a lightweight construction, making it portable and durable. This is especially advantageous for those engaged in tactical training or shooting competitions, where quick reloading is essential for optimal performance.Key Features and Functionality:The Gun Loading Tube boasts several state-of-the-art features engineered to enhance user experience and firearm efficiency. These primary features include:1. Fast Reloading: The Gun Loading Tube employs an innovative spring-loaded mechanism that enables rapid reloading of firearms. The high-quality spring ensures consistent tension, facilitating smooth and seamless ammunition insertion.2. Ammunition Capacity: This accessory ensures an optimal ammunition capacity, reducing the need for frequent reloading. The design allows the Gun Loading Tube to accommodate a significant number of rounds, varying based on firearm compatibility.3. Universal Fit: The Gun Loading Tube is designed to accommodate a wide range of firearms, from rifles to pistols, ensuring versatility and compatibility. Its adaptability to different firearm models makes it a practical addition to any gun owner's toolkit.4. Ergonomic Grip: The Gun Loading Tube incorporates an ergonomically designed handle that provides users with a comfortable grip, minimizing fatigue during extended use. This feature is especially beneficial for individuals who spend significant time at the range or engage in prolonged shooting sessions.5. Enhanced Safety: The loading process is made much safer with the Gun Loading Tube. The design prevents accidental discharges and ensures that the ammunition is securely and reliably loaded into the firearm. This safety feature is of paramount importance and maintains responsible firearm usage.Company's Commitment to Quality:As the provider of the Gun Loading Tube, the company prides itself on the meticulous quality control measures employed during the manufacturing process. The product undergoes rigorous testing to ensure durability, reliability, and long-lasting performance. Furthermore, the company adheres to strict industry standards and regulations, ensuring that the Gun Loading Tube meets or exceeds all safety requirements.Conclusion:In conclusion, the Gun Loading Tube represents an exciting development in the firearms industry, offering a revolutionary solution to optimize the loading process. With its fast reloading capabilities, universal fit, ergonomic grip, and enhanced safety features, this accessory is set to redefine the way firearm enthusiasts and professionals engage with their weapons. By simplifying and expediting the reloading process while prioritizing safety, the Gun Loading Tube is a must-have accessory for firearm owners looking to enhance their shooting experience.

Innovative Casing Collar Search Equipment for Efficient Operations

Title: Revolutionary Casing Collar Search Equipment: A Game-Changer in the Oil and Gas IndustryIntroduction:As technology continues to evolve, the oil and gas industry is constantly in search of groundbreaking solutions to streamline operations and enhance efficiency. In this pursuit, one company has recently invented an innovative Casing Collar Search Equipment (CCSE), which has the potential to revolutionize the sector. The CCSE, developed by a leading technology organization, is a cutting-edge device that promises to optimize efficiency, reduce operational costs, and improve safety standards in the oil and gas field.1. Overview of the Oil and Gas Industry:The oil and gas industry is a vital component of the global economy. However, the sector faces numerous challenges, such as technological limitations, high operational costs, and safety concerns. To overcome these obstacles, companies are constantly seeking advanced equipment that can cater to their specific needs and improve overall productivity.2. Understanding the Casing Collar Search Equipment (CCSE):The CCSE is a state-of-the-art tool developed by the leading technology organization. This device is designed to accurately detect and locate casing collars, an essential element used in well construction operations. By pinpointing the precise location of casing collars, the CCSE significantly reduces time-consuming and expensive manual searches, streamlining the entire process.3. Key Features and Benefits:The CCSE offers several noteworthy features and benefits that make it a game-changer in the oil and gas industry:a) Enhanced Efficiency: With the CCSE, oil and gas companies can save considerable time and resources by eliminating the need for extensive manual searches to locate casing collars. This increased efficiency helps expedite drilling operations and enhances production rates.b) Cost Savings: The implementation of the CCSE results in significant cost reductions for oil and gas companies. By simplifying and accelerating the search process, organizations can minimize downtime, enhance resource allocation, and streamline overall operations, ultimately leading to substantial cost savings.c) Safety Improvement: Manual casing collar searches are often hazardous and time-consuming, exposing workers to potential accidents and injuries. The CCSE eliminates these risks, ensuring a safer work environment and decreasing occupancy time in high-risk areas.d) Accuracy and Reliability: The CCSE utilizes advanced technology to precisely detect casing collars, enhancing accuracy and reliability in the search process. By eliminating errors and false positives, this innovative equipment enables more efficient well construction and improves overall drilling success rates.4. Industry Impact and Implementation:The introduction of the CCSE marks a significant turning point in the oil and gas industry. It is expected to have a profound impact on drilling companies, well construction operations, and the industry as a whole. Oil and gas organizations can quickly integrate this groundbreaking solution into their current operations, optimizing efficiency and improving overall outcomes.5. Future Development and Collaboration Opportunities:The possibilities for the CCSE extend beyond its current capabilities. The technology organization behind its invention continues to research and develop additional features that will further enhance its efficacy. Moreover, there are opportunities for collaboration between the organization and other industry players, such as oil and gas service providers and drilling contractors, to collectively enhance the CCSE's potential and address specific sector challenges.Conclusion:The development of the Casing Collar Search Equipment has brought forth a new era of efficiency and accuracy in the oil and gas industry. This groundbreaking device offers improved productivity, substantial cost savings, enhanced safety, and heightened reliability in well construction operations. With anticipated future developments and collaboration opportunities, the CCSE is set to have a profound impact on the industry, revolutionizing the way companies locate casing collars and execute drilling operations.

Seamless Shifting Tool Setting Tool: Boost Efficiency in Automated Processes

Title: Revolutionary Shifting Tool Set to Propel Efficiency and Precision in ManufacturingIntroduction:In the fast-paced world of manufacturing, innovation plays a vital role in driving efficiency, productivity, and quality. One recent breakthrough poised to revolutionize the industry is the groundbreaking Shifting Tool Setting Tool (STS), a cutting-edge solution developed by an industry-leading company. This state-of-the-art tool promises to streamline manual processes, enhance precision, and ultimately optimize manufacturing operations across various sectors. By removing the brand name to remain impartial, let's explore the key features and benefits of this innovative tool, as well as the potential impact it could have on the manufacturing landscape.1. Streamlined Operations:The STS introduces an advanced level of automation and precision previously unseen in manufacturing operations. This tool simplifies and accelerates the process of tool setting, minimizing human error and reducing downtime. Its user-friendly interface makes it accessible to both experienced technicians and newcomers, promising seamless integration into existing workflows. With the STS, manufacturers can expect faster setups, reduced idle time, and increased operational efficiency.2. Enhanced Precision:Accurate tool setting is crucial for attaining high-quality end products. The STS employs cutting-edge technology, ensuring precise measurement and calibration, leading to enhanced precision in machining processes. The tool's digital display provides real-time feedback, allowing technicians to make informed adjustments quickly. By significantly minimizing potential errors, manufacturers can improve product quality, increase customer satisfaction, and ultimately boost their competitive edge.3. Improved Safety:Manual tool setting can be a hazardous task, exposing technicians to potential injuries. The STS mitigates these risks by reducing the need for manual intervention significantly. An integrated calibration system ensures that the tool is always properly aligned, eliminating potential accidents caused by incorrect settings. Enhanced safety features, such as motion sensors and automatic shutdown mechanisms, further minimize the chances of harm to operators and safeguard the overall manufacturing environment.4. Integration and Versatility:Manufacturers often work with a variety of tooling systems and machines, and compatibility can be a concern. The STS seeks to address this challenge by providing extensive integration options. This versatile tool is compatible with various industry-standard machines and can seamlessly adapt to different tooling technologies. The STS's adaptability allows manufacturers to achieve a higher degree of workflow flexibility, as well as cost-effectively upgrade existing machinery without significant investments.5. Real-Time Data Insights:To maximize operational efficiency, manufacturers rely on accurate and real-time data insights. The STS generates comprehensive reports and data analysis, providing manufacturers with valuable performance metrics. Technicians can monitor tool life, calibration records, and usage trends, enabling optimal scheduling for tool maintenance and replacement. Moreover, this tool's data-driven approach enables predictive maintenance, preventing unexpected production interruptions and extending the lifespan of tools.6. Future-Proofing Manufacturing:Embracing transformative technologies is crucial for staying ahead in an ever-evolving manufacturing landscape. The STS represents a significant leap towards Industry 4.0 integration, facilitating an efficient transition to smart manufacturing practices. With features like cloud connectivity and machine learning capabilities, it sets the stage for increased automation, augmented reality-based assistance, and remote operation options. By investing in this tool, manufacturers can future-proof their operations, adapt to changing market dynamics, and remain at the forefront of innovation.Conclusion:The Shifting Tool Setting Tool (STS) introduces a new era of efficiency, precision, and safety in manufacturing. With streamlined operations, enhanced precision, improved safety measures, compatibility, and real-time data insights, this tool aims to optimize manufacturing processes and maximize productivity. Additionally, the STS serves as a springboard for future technological advancements, empowering manufacturers to embrace smart manufacturing practices. As the industry continues to evolve, the STS promises to be an essential tool in driving manufacturing excellence, improving product quality, and ensuring sustained success.

Essential Guide to Perforating Gun Deployment

Perforating Gun Deployment Enhances Production Capabilities for {} The oil and gas industry is constantly evolving, with companies always searching for new technologies and methodologies to enhance their production capabilities. One such technology that has been making waves in the industry is the deployment of perforating guns, which play a crucial role in the extraction of oil and gas from reservoirs. With the advanced technologies of {}, the deployment of perforating guns has become more efficient and effective, leading to significant improvements in production capabilities.As a leading provider of oilfield services, {} has been at the forefront of developing and implementing advanced technologies for the oil and gas industry. With a strong commitment to innovation and efficiency, {} has been able to provide cutting-edge solutions to their clients, helping them optimize their production processes and maximize their returns.The deployment of perforating guns is a crucial step in the production of oil and gas. These guns are used to create perforations in the well casing and surrounding rock formations, allowing the oil and gas to flow into the wellbore. This process is essential for accessing the reservoir and extracting the valuable resources trapped underground.In the past, the deployment of perforating guns was a complex and time-consuming process, often requiring multiple runs and extensive logistical coordination. However, with the advanced technologies developed by {}, the deployment of perforating guns has become more streamlined and efficient. This has led to significant improvements in the overall production capabilities of the company's clients, allowing them to access more resources in a shorter amount of time.One of the key technologies developed by {} is the advanced telemetry systems that allow for precise positioning and control of the perforating guns. This technology enables operators to accurately place the perforations in the desired locations, maximizing the flow of oil and gas into the wellbore. Additionally, the use of advanced materials and design techniques has resulted in more robust and reliable perforating guns, further enhancing their effectiveness in the field.The deployment of perforating guns has also been integrated with {}'s data analytics and monitoring systems, allowing for real-time feedback and adjustments during the operation. This level of monitoring and control has proven to be invaluable for optimizing the performance of the perforating guns and ensuring the efficient extraction of resources from the reservoir.With these advancements in perforating gun deployment, {} has been able to help their clients achieve significant improvements in their production capabilities. By utilizing the latest technologies and methodologies, {} has been able to enhance the efficiency and effectiveness of the extraction process, ultimately leading to higher returns for their clients.In addition to the technological advancements, {} has also placed a strong emphasis on safety and environmental responsibility in their perforating gun deployment operations. By adhering to strict safety protocols and utilizing environmentally-friendly practices, {} has been able to ensure that their operations have minimal impact on the surrounding environment.Overall, the deployment of perforating guns has been a game-changer for the oil and gas industry, and with the advanced technologies developed by {}, the process has become even more efficient and effective. With a strong commitment to innovation, efficiency, and environmental responsibility, {} continues to lead the way in providing cutting-edge solutions for the oil and gas industry, helping their clients optimize their production capabilities and achieve greater success in their operations.

Essential Drilling Circulation Equipment for Successful Operations

Drilling Circulation Equipment is vital for the success of oil and gas exploration and production. This equipment plays a key role in maintaining the integrity of the wellbore and ensuring the safe and efficient extraction of hydrocarbons from the earth. The proper selection and use of drilling circulation equipment can significantly impact the overall success of a drilling operation.{Company introduction} is a leading provider of drilling circulation equipment to the oil and gas industry. With a strong focus on innovation and quality, the company has built a reputation for delivering reliable and high-performance equipment that meets the demanding requirements of drilling operations around the world.One of the key products offered by {Company} is the {Drilling Circulation Equipment}. This equipment is designed to provide efficient and reliable circulation of drilling fluid during the drilling process. It is essential for maintaining well control, removing cuttings from the wellbore, and lubricating the drill string. The {Drilling Circulation Equipment} is built to withstand the harsh operating conditions encountered in drilling operations, ensuring reliable performance in the most challenging environments.The {Drilling Circulation Equipment} offered by {Company} includes a range of components such as mud pumps, mud agitators, mud cleaning systems, and related accessories. These components are designed to work seamlessly together to provide a complete circulation system that meets the specific requirements of each drilling operation. From onshore to offshore, from conventional to unconventional drilling, {Company}’s {Drilling Circulation Equipment} is trusted by drilling professionals to deliver reliable and efficient performance.One of the key advantages of {Drilling Circulation Equipment} from {Company} is its focus on innovation and technology. The company continuously invests in research and development to improve the performance and efficiency of its equipment. This commitment to innovation has led to the development of advanced drilling circulation systems that offer greater control, reliability, and efficiency, ultimately leading to safer and more productive drilling operations.In addition to its focus on innovation, {Company} is also committed to providing exceptional customer support and service. The company works closely with its customers to understand their specific needs and challenges, and then provides tailored solutions to meet those requirements. Whether it’s providing expert technical support, delivering timely maintenance and repair services, or offering comprehensive training and education programs, {Company} is dedicated to ensuring the success of its customers’ drilling operations.As the oil and gas industry continues to evolve and face new challenges, the demand for reliable and efficient drilling circulation equipment will only continue to grow. With its strong reputation for quality, innovation, and customer support, {Company} is well-positioned to meet this demand and continue to be a trusted partner for drilling professionals around the world.In conclusion, drilling circulation equipment is a critical component of successful drilling operations in the oil and gas industry. {Company} is a leading provider of drilling circulation equipment, offering a range of high-performance products designed to meet the specific requirements of drilling operations. With a focus on innovation, technology, and customer support, {Company} is committed to delivering reliable, efficient, and safe drilling circulation solutions for its customers.

: "New 7/16 Cable Head: Latest Updates and Information

16 Cable Head to Revolutionize High-Speed InternetThe demand for high-speed internet continues to grow as people rely more on digital communication, entertainment, and remote work. To meet this demand, {company name} is introducing a groundbreaking new product - the 16 Cable Head. This innovative technology is poised to revolutionize the internet industry and provide users with faster and more reliable internet connections.{Company name} is a leading provider of networking solutions and has been at the forefront of technology innovation for over two decades. The company has a strong track record of developing cutting-edge solutions that enhance the way we connect and communicate. With the introduction of the 16 Cable Head, {company name} is once again proving its commitment to driving technological advancements and improving the internet experience for users around the world.The 16 Cable Head is a breakthrough in high-speed internet technology. It is designed to significantly increase internet speeds and improve the reliability of internet connections. This is achieved through advanced signal processing and data compression techniques, which allow for more efficient data transmission over cable lines. As a result, users can expect a noticeable improvement in their internet browsing, streaming, and downloading experiences.One of the most exciting features of the 16 Cable Head is its ability to support multi-gigabit internet speeds. This means that users will be able to enjoy lightning-fast internet connections, even during peak usage times. Whether it's streaming 4K video, gaming online, or video conferencing with colleagues, the 16 Cable Head promises to deliver a seamless and uninterrupted experience.In addition to its impressive speed capabilities, the 16 Cable Head also boasts advanced security features to protect users' data and privacy. With the increasing threats of cyber attacks and data breaches, this is a crucial aspect of modern internet technology. The 16 Cable Head provides robust encryption and firewall protection to keep users' information safe from unauthorized access.Another key benefit of the 16 Cable Head is its compatibility with existing cable infrastructure. This means that internet service providers can easily upgrade their networks to support the new technology, without the need for extensive infrastructure changes. As a result, users can look forward to a seamless transition to the faster and more reliable internet offered by the 16 Cable Head.The introduction of the 16 Cable Head comes at a time when the demand for high-speed internet is at an all-time high. With more people working and studying from home, the need for reliable and fast internet connections has never been more critical. {Company name} is proud to be at the forefront of meeting this demand and is committed to providing users with the best possible internet experience.As internet usage continues to grow, {company name} is dedicated to pushing the boundaries of technology and delivering innovative solutions that enhance the way we connect and communicate. The 16 Cable Head is a testament to this commitment and is set to revolutionize the high-speed internet industry. With its advanced technology, lightning-fast speeds, and robust security features, the 16 Cable Head is poised to change the way we experience the internet for years to come.

The Latest in Perforating Technology: A Guide to Wireline Perforating

Wireline Perforating Services: A Step towards Efficient and Safe Well OperationsAs the demand for energy resources continues to grow, oil and gas companies are constantly seeking innovative technologies and processes to maximize production from their wells. In this quest for efficiency, wireline perforating services have emerged as a crucial tool for enhancing well productivity and ensuring safe and reliable operations.Wireline perforating refers to the process of creating holes or perforations in oil and gas well casing and surrounding rock formations to facilitate the flow of hydrocarbons. It is a critical operation that is performed to connect the reservoir to the wellbore, allowing for the extraction of valuable resources. The effectiveness of wireline perforating directly impacts the overall productivity and profitability of a well, making it an essential aspect of well completion and production.At [Company Name], we understand the significance of wireline perforating services in the oil and gas industry. With our commitment to delivering high-quality solutions and our extensive experience in the field, we have positioned ourselves as a leading provider of wireline perforating services. Our comprehensive range of tools and equipment, combined with our team of skilled professionals, enables us to provide reliable and efficient perforating solutions tailored to the unique needs of each well and reservoir.Our wireline perforating services are designed to offer several key benefits to our clients. Firstly, by utilizing advanced technology and techniques, we can precisely control the size, shape, and depth of the perforations, allowing for optimal reservoir access and enhanced production rates. Additionally, our perforating solutions are engineered to minimize formation damage and ensure the integrity of the well, contributing to long-term productivity and sustainability.One of the primary advantages of wireline perforating is its ability to enhance the overall efficiency of well operations. By using wireline technology, perforating operations can be carried out without the need to remove the wellhead, saving time and reducing costly downtime. This streamlined approach to perforating allows for quicker and more cost-effective well completions, ultimately contributing to improved project economics and profitability.Furthermore, wireline perforating services play a crucial role in ensuring the safety and environmental responsibility of well operations. By utilizing wireline technology, perforating activities can be conducted with greater precision and control, minimizing the risk of accidents and mitigating environmental impact. This is particularly important in offshore and environmentally sensitive areas, where well integrity and safety are top priorities.In addition to our expertise in wireline perforating, we are dedicated to upholding the highest standards of safety and compliance in all our operations. Our team undergoes rigorous training and adheres to strict protocols to ensure that perforating activities are carried out in accordance with industry regulations and best practices. By prioritizing safety and environmental stewardship, we are committed to delivering wireline perforating services that meet the highest standards of quality and reliability.As the demand for energy continues to drive the exploration and production of oil and gas resources, the role of wireline perforating services in the industry has never been more crucial. Through our steadfast commitment to excellence and innovation, we at [Company Name] are proud to offer tailored wireline perforating solutions that enable our clients to optimize their well performance and achieve their production goals.In conclusion, wireline perforating services represent a key step towards efficient and safe well operations in the oil and gas industry. With their ability to enhance productivity, minimize risk, and uphold environmental responsibility, wireline perforating solutions have become an indispensable tool for maximizing the potential of oil and gas wells. Through our unwavering dedication to quality and safety, [Company Name] is poised to continue leading the way in delivering cutting-edge wireline perforating services that meet the evolving needs of the industry.