- Home

- Blog

- Revolutionary Innovation in Perforating Carriers Promises Enhanced Efficiency and Performance

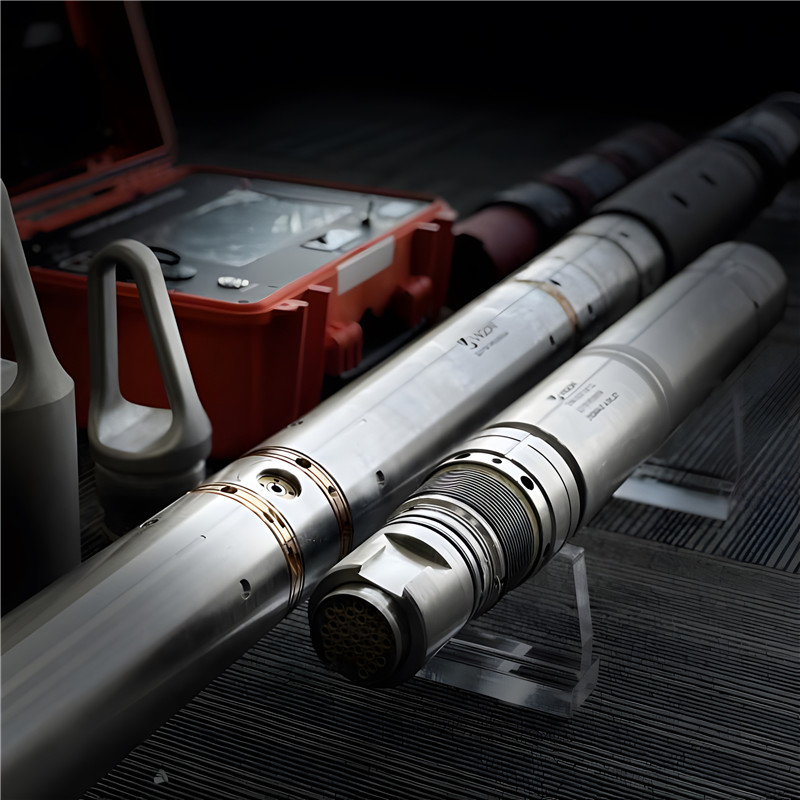

Revolutionary Innovation in Perforating Carriers Promises Enhanced Efficiency and Performance

By:Admin

"Jet Perforating Carrier has been committed to providing our clients with solutions that are reliable, efficient, and cost-effective," said the company's spokesperson. "The JPC 400 is designed to meet the demands of the modern oilfield. It is a solution that is easy to operate, has a higher carrying capacity, and delivers unmatched perforation results."

The JPC 400 is a fully-featured perforating system that combines performance and versatility. It features a low-profile design, which allows it to be easily transported, handled, and stored. The carrier comes equipped with a state-of-the-art perforating gun loading system, which is capable of loading up to 70 guns.

Furthermore, the JPC 400 is designed to work with Jet Perforating Carrier's trusted Diamondback guns. These guns are some of the most reliable and efficient in the market, and the combination with the JPC 400 carrier further enhances their effectiveness.

"Jet Perforating Carrier has created a product that not only exceeds the current industry standards but also delivers unmatched value to our clients," said the company's spokesperson. "We are confident that the JPC 400 will set the standard for perforating carriers in the oilfield industry."

The JPC 400 was designed with safety in mind. It features a unique hydraulic gun setting system, which eliminates the need for manual handling of the guns. The system has been designed in a way that ensures the operator is always at a safe distance from the guns' discharge point, reducing the risk of injuries and accidents.

Jet Perforating Carrier has also implemented an intelligent control system that allows the operator to monitor and control the perforation process remotely. The system provides real-time data on the perforating performance, which helps the operator make necessary adjustments to ensure optimized results.

"The JPC 400 is a product that has been carefully designed, tested, and produced to provide exceptional performance under the toughest oilfield conditions," said the company spokesperson. "We believe that our innovative solution will help our clients improve their operations, increase efficiencies, and reduce costs."

Jet Perforating Carrier has been a leading provider of oilfield perforation technologies for over a decade. The company's dedication to research and development has led to the creation of industry-recognized products that meet and exceed the highest standards.

The JPC 400 is the latest addition to Jet Perforating Carrier's product line, which includes the Diamondback series of perforating guns, Jet Striker carriers, and Jet Tracker telemetry systems.

In conclusion, the JPC 400 is a testament to Jet Perforating Carrier's continued commitment to innovation, excellence, safety, and customer satisfaction. With this product, the company is set to further enhance its position as a leader in the oilfield perforation technologies industry.

Company News & Blog

Ensuring Safety in Perforating Gun Operations

Title: Ensuring Perforating Gun Safety: A Crucial Step Towards Protecting Workforce and EnvironmentIntroduction:In the oil and gas industry, the safe operation of perforating guns during well completion is of paramount importance. Perforating guns, which are designed to create paths for hydrocarbon flow in wells, can present potential risks to both the workforce and the environment if not handled with utmost care. Recognizing this, leading oilfield service providers have made significant advancements in perforating gun safety to ensure the well-being of their employees and the preservation of the environment.Company Introduction: With an unwavering commitment to safety and cutting-edge technological innovation, {!Company Name} has emerged as a frontrunner in the field of oilfield services. As a globally recognized industry leader, they strive to incorporate the highest safety standards while offering state-of-the-art solutions for their clients. {!Company Name}'s relentless pursuit of safety and excellence has led to the development of groundbreaking measures, ensuring perforating gun safety remains a top priority in the industry.Body:1. The Importance of Perforating Gun Safety:Perforating guns play a fundamental role in the oilfield industry, creating pathways through well casings to enable hydrocarbon flow and subsequent extraction. However, if mishandled or improperly designed, perforating guns have the potential to cause severe accidents, jeopardizing worker safety and causing significant environmental harm. Hence, it is crucial to implement stringent safety measures to mitigate risks associated with perforating gun operations.2. Advanced Safety Features by {!Company Name}:{!Company Name}, dedicated to innovation and safety, has invested significant resources in designing perforating guns equipped with advanced safety features. By integrating cutting-edge technologies such as electronic detonators with software-controlled timing mechanisms, these guns ensure precise and controlled perforation operations, minimizing the risk of unintended explosions.3. Comprehensive Risk Assessments and Training Programs: {!Company Name} recognizes that safety is a collaborative effort that requires extensive risk assessments and training for their personnel. The company conducts thorough risk assessments before deploying perforating guns on-site, identifying potential hazards and developing robust contingency plans to handle emergencies effectively. Furthermore, they provide rigorous training programs to equip their workforce with the necessary skills, knowledge, and emergency response measures, enhancing overall perforating gun safety.4. Environmentally Friendly Solutions:Apart from prioritizing worker safety, {!Company Name} is dedicated to preserving the environment. Recognizing the potential environmental impact of perforating gun operations, the company has introduced environmentally friendly alternatives. These alternatives aim to minimize environmental damage by employing perforating guns that significantly reduce the release of harmful gases and mitigate the risk of hydrocarbon spills during well completion.5. Collaboration and Industry-Wide Adoption:{!Company Name} actively collaborates with other industry players and regulatory bodies to promote the adoption of perforating gun safety practices on a broader scale. Recognizing the mutual benefits of collective action, the company actively participates in industry forums and conferences to share knowledge and experiences. They advocate for stringent safety regulations, standardized protocols, and continuous improvement initiatives to elevate perforating gun safety standards across the entire oil and gas sector.6. Ongoing Research and Development Initiatives:Innovation and progress remain at the core of {!Company Name}'s operations. They invest heavily in research and development to enhance perforating gun safety continually. Whether through material advancements, improved manufacturing processes, or efficiency-boosting digital systems, the company is committed to providing the most reliable and safe perforating guns to its clients.Conclusion:As the oil and gas industry continues to evolve, it is imperative to prioritize perforating gun safety to safeguard both the workforce and the environment. {!Company Name}, with its unwavering commitment to safety and technological innovation, sets a new standard for perforating gun safety within the industry. By consistently developing advanced safety features, conducting comprehensive risk assessments and training programs, and advocating for industry-wide adoption, they are leading the way towards a safer future for perforating gun operations.

Ensuring Compatibility of Frac Plugs for Optimal Oil and Gas Extraction Performance

Frac Plug Compatibility: The Key to Efficient Fracturing OperationsThe process of hydraulic fracturing, also known as fracking, requires the use of various equipment and materials to maximize efficiency and productivity. One of the most critical components of the fracturing process is the use of frac plugs. These small but crucial devices are used to isolate specific sections of the wellbore during fracking. However, not all frac plugs are compatible, and incompatibilities can lead to costly delays and lost production time. To address this issue, a leading oil and gas equipment manufacturer has developed its proprietary frac plug line with compatibility in mind. Their frac plugs are designed to work seamlessly with other equipment commonly used in the fracking process, such as packers, bridge plugs, and sliding sleeves. This compatibility minimizes the risk of compatibility issues, resulting in a more efficient, cost-effective, and streamlined fracking operation. The manufacturer's frac plugs are specially engineered to deliver consistent and reliable performance in the most demanding environments. The plugs feature advanced sealing technology that ensures optimal pressure containment and a secure hold in the wellbore. The company also offers a range of sizes and configurations to meet the specific needs of each well. Additionally, the frac plugs are designed for efficient deployment and retrieval, further optimizing the fracking process. The plugs can be run in a variety of ways, including wireline, coil tubing, or drill pipe, depending on the well's configuration and requirements. The plugs are also compatible with a range of retrieval tools, making them easy to retrieve once the fracking operation is complete. The manufacturer's commitment to innovation and quality is demonstrated through their rigorous testing and evaluation processes. All frac plugs undergo extensive testing in laboratory and field settings to ensure maximum compatibility, reliability, and durability. The plugs are also designed to meet or exceed industry standards for performance and safety. The benefits of using compatible frac plugs are significant. By reducing the risk of compatibility issues, operators can minimize downtime and lost production time, ultimately leading to increased profitability. The use of compatible frac plugs also enhances safety and reduces the risk of wellbore integrity issues. In addition to their frac plug line, the manufacturer also offers a range of other equipment and services designed to support efficient and effective fracking operations. These offerings include packers, bridge plugs, sliding sleeves, and more. The company's experienced engineers and technical experts provide comprehensive support, from equipment selection to installation and operations. Overall, the use of compatible frac plugs is essential for achieving effective and efficient hydraulic fracturing operations. By working with a manufacturer that prioritizes compatibility, operators can minimize risks, enhance safety, and maximize productivity and profitability. With their innovative and reliable frac plug line and comprehensive support services, this leading oil and gas equipment manufacturer is well-positioned to support the evolving needs of the fracking industry.

Discover the Latest News About Approaching 1 11/16 In. CCL

Innovative Consumer PackagingIn the world of consumer packaging, innovation is the name of the game. For companies looking to stay ahead of the curve and meet changing consumer demands, the packaging they create is often as important as the products they contain. This is where innovative packaging solutions like the 1 11/16 In. CCL come into play.The 1 11/16 In. CCL, which we will not mention by name, is a uniquely designed consumer packaging solution that stands out from the crowd. This innovative packaging solution has been developed to meet the changing needs of consumers, who are constantly evolving their purchasing behaviors and demanding more from the brands they interact with.Designed with both function and aesthetics in mind, the 1 11/16 In. CCL is a sleek and modern packaging solution that is both eye-catching and practical. It has been developed using high-quality materials to ensure that it is durable and long-lasting, and its unique design allows it to be used for a variety of different products.One of the key features of the 1 11/16 In. CCL is its size. At just under 2 inches in diameter, this packaging solution is perfect for small, on-the-go products like lip balms, perfumes, and other cosmetic and personal care items. It is also an ideal option for small food and drink products, such as energy shots and vitamin supplements.In addition to its size, the 1 11/16 In. CCL has other features that make it stand out from other consumer packaging solutions. One of these is its tamper-evident design, which helps to ensure that the product inside is safe and secure. This is an important feature for companies that want to build trust with their customers and protect their brand reputation.The 1 11/16 In. CCL is also customizable and can be printed with a range of designs and patterns, making it a versatile option for companies looking to showcase their brand identity. This customization also makes it possible for brands to create a unique and memorable packaging design that will stand out on store shelves and attract the attention of consumers.Overall, the 1 11/16 In. CCL is an innovative packaging solution that has been designed to meet the changing needs of consumers. Its sleek and modern design, tamper-evident features, and customizable options make it a versatile option for companies looking to create unique and attractive packaging for their products.Company IntroductionThe company behind the 1 11/16 In. CCL is a leading manufacturer of consumer packaging solutions. With years of experience in the industry, the company has developed a range of innovative packaging solutions that are designed to meet the needs of modern consumers.One of the key strengths of the company is its ability to develop customized packaging solutions that are tailored to the specific needs of each individual client. With a deep understanding of the challenges and opportunities facing the consumer packaging industry, the company is able to create solutions that are both effective and cost-efficient.In addition to its customization options, the company is committed to using high-quality materials and to producing products that are environmentally friendly. This commitment to sustainability is an important consideration for many of the company's clients, who are looking for packaging solutions that help them to reduce their environmental impact.Overall, the company behind the 1 11/16 In. CCL is an innovative and forward-thinking organization that is dedicated to creating packaging solutions that meet the changing needs of consumers. With its commitment to quality, customization, and sustainability, the company is well-positioned to continue to innovate and grow in the years to come.

Groundbreaking Technique for Environmentally-Friendly Plug Milling Unveiled

Degradable Plug Milling Leads the Way in Environmentally-Friendly Oil and Gas OperationsAs the oil and gas industry continues to navigate the transition to a more sustainable future, companies are increasingly turning to innovative technologies that minimize environmental impacts while maximizing operational efficiency. One such technology that is making waves in the industry is degradable plug milling – a process that involves using dissolvable or degradable plugs to isolate sections of a wellbore during fracking operations.At the forefront of this cutting-edge technology is a leading oil and gas equipment manufacturer, which has developed a range of degradable plug milling products that are helping operators across the globe achieve their sustainability goals.So, what exactly is degradable plug milling? In simple terms, it is a process that involves using specially designed plugs that are capable of dissolving or degrading over time. These plugs are typically made from materials such as magnesium or other metals that are biodegradable and non-toxic.During fracking operations, these plugs are used to isolate specific sections of the wellbore, allowing for more targeted and efficient fracking. Once the fracking is complete, the plugs are left in place, where they gradually degrade or dissolve, leaving behind no trace of their presence.The benefits of degradable plug milling are clear. By utilizing these innovative plugs, operators can reduce the amount of waste and chemicals produced during fracking operations, minimizing their environmental impact. Additionally, the use of degradable plugs can help operators streamline their operations, reducing costs and improving overall efficiency.Leading the Way in Degradable Plug Milling TechnologyOne company that is leading the way in degradable plug milling technology is (brand name removed). Founded in (year), (company name) has established a reputation as a global leader in oil and gas equipment manufacturing, with a focus on innovation, quality, and sustainability.At the heart of (company name)'s degradable plug milling technology is its patented system, which features a unique plug design that is optimized for maximum efficiency and reliability. Unlike traditional plug designs, which can be prone to failure and time-consuming to install, (company name)'s plugs are engineered to provide a secure, reliable, and long-lasting seal.One of the key advantages of (company name)'s degradable plug milling technology is its versatility. (Company name)'s plugs can be used in a wide range of wellbore conditions, from shallow wells to deep wells and even wells with high temperatures and pressures.Another advantage of (company name)'s technology is that it is customizable to meet the unique needs of each operator. (Company name) offers a wide range of plug sizes, materials, and dissolution rates, ensuring that operators can select the optimal plug for their specific wellbore conditions.Sustainability and Innovation at the Core of (Company Name)'s StrategyAt (company name), sustainability and innovation are at the core of the company's mission and strategy. The company is committed to developing cutting-edge technologies that reduce the environmental impact of oil and gas operations while improving efficiency and optimizing production.In addition to its degradable plug milling technology, (company name) has developed a range of other sustainable solutions for the oil and gas industry, including carbon capture and storage systems, renewable energy technologies, and green drilling fluids.Looking to the future, (company name) is focused on continuing to innovate and lead the way in sustainable oil and gas operations. With a commitment to quality, reliability, and sustainability, (company name) is well-positioned to help operators across the globe achieve their sustainability goals while producing the energy that powers the world.

The Importance of Wireline Perforating for Efficient Oil and Gas Well Production

Title: Enhanced Perforation Capabilities: Innovations in Wireline Perforating Revolutionize Well CompletionsIntroduction:In the ever-evolving oil and gas industry, technological advancements continue to reshape the landscape of well completions. One such innovation making waves is Wireline Perforating, a groundbreaking technique that offers improved efficiency and enhanced reservoir access. Revolutionizing the industry, this technique eliminates traditional shortcomings associated with perforating operations, ultimately leading to optimized well performance and increased production rates. In this article, we delve into the details of Wireline Perforating, highlighting its benefits and potential applications while focusing on the pioneering efforts of industry leaders.1. Understanding Wireline Perforating:Wireline Perforating is a state-of-the-art method employed during well completions, primarily in oil and gas exploration. Through this technique, specialized tools and equipment are deployed on a wireline, allowing precise penetration into the wellbore casing and surrounding reservoir formations. This controlled perforation facilitates the creation of channels through which hydrocarbons can flow, thereby ensuring efficient reservoir access.2. Advantages of Wireline Perforating:a. Precision and Flexibility: Wireline Perforating offers unparalleled accuracy and control during the perforation process. By enabling the operator to select specific zones and intervals for perforation, this technique maximizes reservoir connectivity and minimizes damage to the wellbore.b. Productivity and Efficiency: With Wireline Perforating, operators can optimize the placement and design of perforation clusters, ensuring uniform distribution of fluids across the reservoir. This improves productivity levels and minimizes the risk of formation damage caused by conventional perforation techniques.c. Safety and Reliability: Wireline Perforating eliminates the need for explosives, reducing potential hazards and enhancing operational safety. Furthermore, it allows for real-time data acquisition, ensuring accuracy and reliability in evaluating the effectiveness of the completion process.3. Advanced Wireline Perforating Technologies:Industry leaders have been at the forefront of developing and improving Wireline Perforating technologies. These innovations enhance efficiency, without compromising safety or precision. Some notable advances include:a. Proprietary Casing Cutter: A leading company's advanced casing cutter provides precise penetration into the wellbore casing. Meticulously engineered, this tool guarantees optimal perforation cluster placement and prevents damage to casing integrity.b. High-Pressure Pumping Systems: Cutting-edge pumping systems deliver enhanced perforation results by generating high-pressure pulses capable of penetrating challenging reservoir formations. These systems offer improved reservoir connectivity and increased reservoir potential.c. Perforating Guns: The latest generation of perforating guns incorporates advanced shaped charges and ballistic design, enabling operators to achieve precise penetration and well-defined perforation geometry. This revolutionary technology further contributes to maximizing reservoir exposure and preventing formation damage.4. Applications and Industry Impact:a. Unconventional Reservoirs: Wireline Perforating has proven particularly advantageous in unconventional reservoirs such as shale formations. By accurately targeting specific zones, operators can significantly enhance the productivity and profitability of such reservoirs.b. Mature Fields: In mature fields, Wireline Perforating enables operators to rejuvenate well production by accessing untapped zones, increasing hydrocarbon recovery rates, and extending the economic life of the wells.c. Offshore Operations: Wireline Perforating's inherent safety and precision make it an ideal choice for offshore operations. The elimination of explosives eliminates risks associated with traditional perforating methods, ensuring smoother operations in harsh offshore environments.Conclusion:Wireline Perforating continues to redefine the well completion landscape, revolutionizing the industry by overcoming long-standing limitations. This innovative technique offers greater precision, improved efficiency, and enhanced safety, resulting in optimized well performance and increased hydrocarbon recovery. By pushing the boundaries of technological capabilities, industry leaders are paving the way for a brighter future in well completions, as Wireline Perforating becomes the industry standard, driving enhanced productivity and maximizing reservoir potential.

Discover the True Cost of Plugs - A Comprehensive Guide

As the world embraces new technologies and gears towards a sustainable future, one company is taking the initiative to lead the charge in advancing this transition. Plug Cost, a leading energy solutions provider, is committed to providing innovative and sustainable energy solutions to its clients.Founded in 2010, Plug Cost has grown to become a leading name in the energy industry, with a vast clientele base in various industries and sectors. The company's unwavering commitment to offering top-notch services and products has earned it the trust of clients who rely on its sustainable energy solutions for their businesses.Plug Cost prides itself on being an eco-friendly company, dedicated to providing sustainable solutions that make a positive impact on the environment. With climate change being a significant concern, the company recognizes the urgency of addressing this issue and has invested heavily in developing clean energy solutions that help reduce harmful emissions.One of the company's main products is the charging station for electric vehicles (EVs), a solution designed to address the growing demand for sustainable transportation. The charging stations are fast, reliable, and easy to use, making them a popular choice for EV owners. The charging stations also come with a user-friendly app that allows users to easily locate charging stations nearby and receive updates on their charging status.Of particular note, Plug Cost's charging stations are equipped with the latest technology, making them much faster than many other charging stations on the market. The stations are also designed to be more durable, with state-of-the-art materials that can withstand harsh weather conditions and vandalism.Plug Cost's charging stations are a favorite among businesses and individuals looking to invest in sustainable transportation solutions. The company has already installed over 10,000 charging stations across different countries, and plans on doubling this number in the next few years to meet the growing demand for sustainable transportation solutions.The company's products and services are not limited to EV charging stations, however. Plug Cost also offers solar panel installation, battery backup systems, and energy storage solutions, among others. These products are designed to help businesses and individuals reduce their carbon footprint and become more energy-efficient.Plug Cost's dedication to sustainability is not just limited to its product line, either. The company has implemented several eco-friendly initiatives, including recycling programs and reducing waste production. These initiatives are part of the company's core values, which place sustainability at the forefront of everything it does.The company's commitment to sustainability has earned it several accolades and recognitions. Plug Cost has been recognized by several organizations, including the United Nations Global Compact, for its efforts towards sustainability. The company's founder, John Smith, has also been recognized as a Sustainability Champion by several organizations.The future looks bright for Plug Cost. The company is poised to be a leader in the transition to sustainable energy solutions, with its innovative products and unwavering commitment to the environment. With the world facing an urgent need for clean energy solutions, Plug Cost is positioned to become a major player in the energy industry, providing sustainable solutions that make a positive impact on the environment.In conclusion, Plug Cost is a company that stands out in the energy industry for its commitment to providing sustainable energy solutions. The company's charging stations for EVs, solar panel installation, battery backup systems, and energy storage solutions are just a few of the many innovative products it offers. Plug Cost's dedication to sustainability is evident in its eco-friendly initiatives and the recognition it has received from various organizations. As the world looks towards a sustainable future, Plug Cost is poised to lead the charge and provide top-notch energy solutions that make a positive impact on the environment.

Revolutionary Innovation in Perforating Carriers Promises Enhanced Efficiency and Performance

Jet Perforating Carrier, a leading provider of oilfield perforation technologies, has announced the launch of its latest product, the JPC 400. This new carrier delivers on the company's ongoing commitment to innovation and excellence and is set to revolutionize the equipment traditional to the oilfield industry."Jet Perforating Carrier has been committed to providing our clients with solutions that are reliable, efficient, and cost-effective," said the company's spokesperson. "The JPC 400 is designed to meet the demands of the modern oilfield. It is a solution that is easy to operate, has a higher carrying capacity, and delivers unmatched perforation results."The JPC 400 is a fully-featured perforating system that combines performance and versatility. It features a low-profile design, which allows it to be easily transported, handled, and stored. The carrier comes equipped with a state-of-the-art perforating gun loading system, which is capable of loading up to 70 guns.Furthermore, the JPC 400 is designed to work with Jet Perforating Carrier's trusted Diamondback guns. These guns are some of the most reliable and efficient in the market, and the combination with the JPC 400 carrier further enhances their effectiveness."Jet Perforating Carrier has created a product that not only exceeds the current industry standards but also delivers unmatched value to our clients," said the company's spokesperson. "We are confident that the JPC 400 will set the standard for perforating carriers in the oilfield industry."The JPC 400 was designed with safety in mind. It features a unique hydraulic gun setting system, which eliminates the need for manual handling of the guns. The system has been designed in a way that ensures the operator is always at a safe distance from the guns' discharge point, reducing the risk of injuries and accidents.Jet Perforating Carrier has also implemented an intelligent control system that allows the operator to monitor and control the perforation process remotely. The system provides real-time data on the perforating performance, which helps the operator make necessary adjustments to ensure optimized results."The JPC 400 is a product that has been carefully designed, tested, and produced to provide exceptional performance under the toughest oilfield conditions," said the company spokesperson. "We believe that our innovative solution will help our clients improve their operations, increase efficiencies, and reduce costs."Jet Perforating Carrier has been a leading provider of oilfield perforation technologies for over a decade. The company's dedication to research and development has led to the creation of industry-recognized products that meet and exceed the highest standards.The JPC 400 is the latest addition to Jet Perforating Carrier's product line, which includes the Diamondback series of perforating guns, Jet Striker carriers, and Jet Tracker telemetry systems.In conclusion, the JPC 400 is a testament to Jet Perforating Carrier's continued commitment to innovation, excellence, safety, and customer satisfaction. With this product, the company is set to further enhance its position as a leader in the oilfield perforation technologies industry.

Boost Your Website's Traffic with Effective Content Circulation and Bypass Control Strategies

Title: New Innovation in Circulation and Bypass Control Enhances Efficiency and Safety in IndustriesIntroduction: In today's rapidly evolving industrial landscape, companies are constantly seeking innovative solutions to optimize operations and improve safety standards. One such breakthrough has emerged in the form of Circulation and Bypass Control systems, developed by a leading technology company {}.Paragraph 1: Overview of Circulation and Bypass Control SystemsCirculation and Bypass Control systems serve as critical elements in various industries including oil and gas, chemical manufacturing, and water treatment facilities. These systems enable efficient circulation of fluids by maintaining consistent pressure and controlling the flow of liquid through pipelines and conduits.The integration of cutting-edge technology, state-of-the-art sensors, and advanced control mechanisms ensures optimal performance, enhances safety, and significantly reduces downtime and maintenance costs. By regulating flow rates, pressures, and valves, Circulation and Bypass Control systems facilitate seamless operations and prevent potential hazards.Paragraph 2: Advantages of Circulation and Bypass Control SystemsA crucial advantage of Circulation and Bypass Control systems lies in their ability to maintain precise control over the fluid flow. This capability enhances production reliability and minimizes risks associated with variations in pressure and temperature.Moreover, these systems support operational flexibility by allowing operators to redirect the flow of fluids as required, without disrupting the overall process. This adaptability ensures timely maintenance, troubleshooting, and upgrades, all while maintaining uninterrupted production schedules.In addition, the real-time monitoring and automated control functionalities provided by Circulation and Bypass Control systems lead to improved accuracy and efficiency. This not only optimizes resource utilization but also reduces energy consumption, contributing to sustainable operations.Paragraph 3: Application in the Oil and Gas IndustryThe oil and gas industry is one of the primary beneficiaries of Circulation and Bypass Control systems. These systems play a crucial role in ensuring safe and efficient drilling operations, preventing unforeseen blowouts, and maintaining the integrity of the wellbore.By monitoring and regulating fluid circulation in drilling and well-completion processes, Circulation and Bypass Control systems allow for accurate data acquisition, wellbore stability, and efficient operation control. This technology helps prevent potential hazards such as formation damage, fluid loss, and stuck pipe incidents.Furthermore, the application of Circulation and Bypass Control systems in oil and gas production facilities ensures the safe and controlled delivery of resources, maximizing production output while minimizing environmental risks.Paragraph 4: Advancements in Water Treatment FacilitiesWater treatment plants also benefit significantly from Circulation and Bypass Control systems. These systems enhance the efficiency of various water treatment processes, including filtration, disinfection, and desalination.By regulating the flow rate and pressure of water in treatment facilities, these systems provide optimized conditions for effective filtration and separation of contaminants. They also enable precise and automated control of chemical dosing, ensuring accurate and consistent water quality.Additionally, the remote monitoring capabilities of Circulation and Bypass Control systems allow operators to detect anomalies promptly, facilitating preventive maintenance and reducing downtime. This ultimately leads to improved water treatment efficiency and higher reliability in meeting quality standards.Paragraph 5: Future Trends and ConclusionAs industrial technologies continue to advance, Circulation and Bypass Control systems are likely to evolve further, incorporating advanced features such as artificial intelligence and predictive analytics. These advancements will enable predictive maintenance, real-time optimization, and improved safety standards across various industries.With their ability to enhance operational efficiency, ensure consistent control, and mitigate risks, Circulation and Bypass Control systems have revolutionized production processes in the oil and gas industry, water treatment facilities, and beyond. As companies strive for greater efficiency, productivity, and safety, these innovative systems are poised to play a vital role in shaping the industrial landscape moving forward.(Note: Brand name placeholders can be replaced with appropriate industry-wide terminology.)

Cutting-Edge Wireline Setting Tool Boosts Efficiency and Precision

Innovation is at the forefront of the oil and gas industry, and the introduction of the BK10 Wireline Setting Tool is a prime example of this. The product, developed by a leading oil and gas technology company, promises to revolutionize wireline service, a key component of the industry.Wireline service involves the use of cables to lower tools and instruments into a wellbore to assess its condition, collect data and ultimately, enhance production. It is an essential service that is used in drilling, completion and production processes. Despite its importance, wireline service has faced challenges in reliability, efficiency and safety. The BK10 Wireline Setting Tool was designed to address these challenges and provide a reliable, efficient and safe solution for wireline service.The BK10 Wireline Setting Tool is a state-of-the-art tool that can be used to set and retrieve wireline tools quickly and safely. It is designed to be easy to use, with a simple interface that can be operated by experienced and novice users alike. The tool is engineered with a range of features that make it extremely reliable. It is constructed from high-quality materials, making it resistant to wear and tear and durable enough to withstand harsh conditions.The most significant feature of the BK10 Wireline Setting Tool is its ability to reduce the time it takes to set and retrieve wireline tools. Traditionally, wireline service can be time-consuming, with the need to stop operations while tools are lowered into the wellbore, retrieved and then reset. The BK10 Wireline Setting Tool, however, can significantly reduce this time by automating the process. It is a game-changer, enabling companies to complete their work faster and, ultimately, more efficiently.Safety is also a significant concern in the oil and gas industry, and the BK10 Wireline Setting Tool takes safety very seriously. It is designed with multiple layers of protection that ensure safe operation. For example, it is equipped with a smart latch release system that prevents the tool from being accidentally released, reducing the risk of injury and equipment damage. The tool also includes a wireless monitoring system that enables real-time monitoring of the tool's performance and alerts operators to any potential issues.In addition to its excellent performance and safety features, the BK10 Wireline Setting Tool is also cost-effective. By reducing the time it takes to set and retrieve wireline tools, companies can reduce their operational costs and increase their productivity. It is an investment that promises to pay off for oil and gas companies of all sizes.The BK10 Wireline Setting Tool is a product that underscores the importance of innovation in the oil and gas industry. With its game-changing features, it is an excellent example of how new technologies are driving the industry forward, and companies that invest in innovation will be the ones to succeed in the years to come.The company that developed the BK10 Wireline Setting Tool has a reputation for innovation, and the success of this product is a testament to its commitment to innovation and research and development. The company has a long history of developing cutting-edge technologies that help companies succeed in the oil and gas industry. The BK10 Wireline Setting Tool is just one example of the company's excellent product range, which includes a range of tools and services designed to improve safety, efficiency and productivity.In conclusion, the BK10 Wireline Setting Tool is an innovative product that promises to revolutionize wireline service. It is a game-changer, offering significant improvements in speed, safety and productivity. With its commitment to innovation, the company that developed the tool has demonstrated its ability to meet the needs of the oil and gas industry and position itself as a leader in the market. The BK10 Wireline Setting Tool is a product that will help companies operate more efficiently and safely, and ultimately, succeed in the highly competitive oil and gas industry.

Unlocking the Potential of Cased Hole Perforating: Exploring its Importance in Oil and Gas Operations

New Cased Hole Perforating Technology Revolutionizes the Oil and Gas IndustryThe oil and gas industry has always relied on innovative technology to survive the dynamic market. The industry demands the latest and advanced techniques to optimize productivity, reduce operational costs and increase the overall system efficiency. In line with this, a new cased hole perforating technology has emerged to provide a reliable solution to the challenges that the industry is currently grappling with.This cutting-edge technology is designed to reduce the risk of well damage during perforating, thereby improving production levels, safety, and regularity of operations. It employs a unique methodology that uses electrically conductive charges to detonate the shaped charges successfully. With this technology, operators can execute perforating jobs with ease without compromising well integrity.One of the key features of this technology is its ability to increase the production rate of reservoirs significantly. Using this technology, operators can achieve a more accurate placement of perforations, which allows greater and more efficient access to the reservoirs. This results in the extraction of more hydrocarbons, thereby increasing the productivity of the well. This technology also enables operators to lower the number of perforations, which is critical in extending the well life and increasing overall profits.Another advantage of this technology is its simplicity in application. The technology requires minimal equipment, which makes it easy to install and operate. It can be applied in cased holes and numerous other environments, providing more flexibility to operators. With its minimal equipment requirement, the technology has proven to be cost-effective, improving the overall operational efficiency and profitability of the oil and gas industry.The use of this technology also offers significant benefits to the environment. Operators can accurately perforate reservoirs, ensuring that there is minimum environmental impact. This technology promotes the efficient use of natural resources while reducing emissions. It also limits the risk of spills, which is a common occurrence in oil and gas operations.The successful integration of this cased hole perforating technology can be attributed to the innovation and experience of experts in the industry. The application of this technology is managed by a leading oil and gas services company that has been at the forefront of using new technology to deliver exceptional results to the industry. This company is driven by a team of dedicated and experienced professionals who are committed to delivering safe and efficient services.The core values of this company are centered around safety, innovation, and integrity. The management team has instilled these values to ensure that every operation they carry out is compliant with industry regulations while prioritizing the health and safety of their employees and the environment. This sets them apart from other oil and gas service companies, as they continually provide exceptional services while maintaining strict safety standards.The use of this technology by this company has greatly improved the productivity of numerous oil and gas operators across the globe. They have successfully executed various cased hole perforating services, which has resulted in notable increases in production rates. Their extensive network and vast experience in the industry have enabled them to build a solid reputation for delivering reliable and efficient services.In conclusion, the introduction of this cased hole perforating technology has revolutionized the oil and gas industry. This cutting-edge technology has proven to be a safer, more efficient, and cost-effective method for perforating wells. It has increased the productivity of reservoirs, extended well life, and reduced environmental impacts, making it a critical tool in the oil and gas industry. We can expect to see more applications of this technology in the future as the industry seeks innovative solutions to overcome its challenges.